- Overview

- Recommended Products

- High-temperature resistance: The device features a wide operating temperature range and is constructed with heat-resistant materials, allowing direct contact with high-temperature melts without damage.

- High pressure and high viscosity resistance: The measuring range is wide, and the probe can withstand the impact pressure of melt flow. The probe structure is optimized (such as flat film, wedge film design), which avoids the adhesion and blockage of high viscosity melt and reduces the measurement error.

- Corrosion and interference resistance: The contact medium is coated with corrosion-resistant alloys or ceramics to resist erosion from corrosive melts like acids, alkalis, and organic solvents. An integrated electromagnetic shielding module provides protection against power grid interference and vibration interference, designed to handle high-frequency vibrations from equipment such as extruders and injection molding machines.

- High precision and repeatability: The measurement accuracy ranges from ±0.1%FS to ±0.25%FS, with linearity and repeatability both under ±0.2%FS and ±0.1%FS respectively. This ensures data consistency and fulfills the requirements of precision manufacturing.

- Temperature compensation feature: The built-in multi-point temperature compensation algorithm counteracts the effect of temperature drift on measurement accuracy in high-temperature environments, ensuring data stability across a wide temperature range.

- Flexible signal output: Supports industrial standard signals including analog (4-20mA, 0-10V,0-5V) and digital (HART, RS485-Modbus, Profibus), enabling direct integration with PLC, DCS, and industrial PCs for seamless automation.

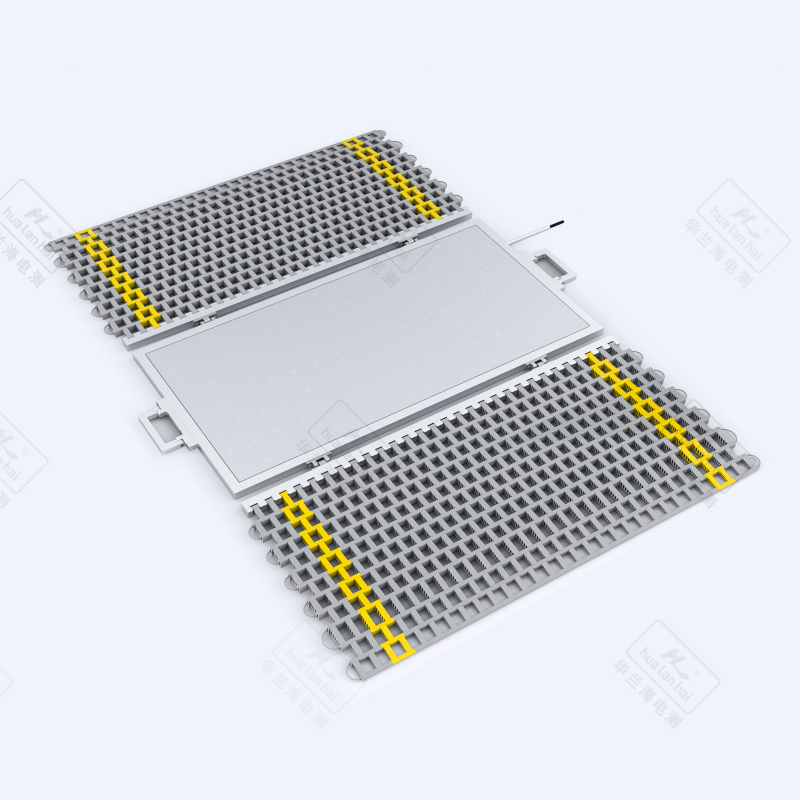

- Integrated/Modular Design: Compact in size, with probe length customizable to fit different equipments barrel and die depth. Flexible installation options include M14/M18/M22 threaded mounting, flange mounting, and clamp mounting, requiring no complex equipment modifications.

- Overload and explosion protection: Features 150%~200%FS overload protection to prevent sensor damage from pressure surges. Some models comply with the Ex d II CT4 explosion-proof standard, making them suitable for flammable and explosive melt processing applications (e.g., solvent-based rubber production).

- Real-time display: Equipped with an LCD/LED head for intuitive pressure reading, eliminating reliance on control systems.

- Alarm output: Set upper and lower pressure thresholds. When exceeded, trigger a switch alarm (e.g., relay output) to control equipment shutdown or adjustment.

- Remote calibration: Enables HART protocol-based remote calibration without sensor disassembly, simplifying maintenance.

- Condition adaptation: To resolve the burning and aging issues caused by inadequate heat resistance in traditional sensors, and to adapt to high-temperature environments such as extruder die heads, injection molding machine barrels, and molten steel pipelines.

- Measurement accuracy issues: To resolve data drift and significant errors caused by high-viscosity melt adhesion and pressure fluctuations, ensuring uniform product thickness (e.g., plastic films, pipes) and consistent density (e.g., rubber products).

- Equipment safety: Real-time monitoring of melt pressure prevents material overflow, die head rupture, or pipeline leakage caused by excessive pressure, as well as raw material delivery issues and product shortages due to insufficient pressure.

- Maintenance cost reduction: The corrosion-resistant and clogging-resistant design minimizes the need for frequent disassembly, cleaning, and replacement of sensors, thereby reducing downtime and maintenance costs. While traditional sensors typically require 1-2 monthly maintenance checks, this product extends maintenance intervals to 3-12 months.

- Automation integration solution: Standardized signal output seamlessly integrates with existing industrial control systems, resolving traditional sensor signal incompatibility and enabling synchronized control, thereby accelerating production automation upgrades.

- Easy installation: Multiple installation methods adapt to different device interfaces, requiring no complex tools and taking only 10-30 minutes to complete setup and debugging. The probes flush design prevents melt residue, making subsequent cleaning convenient.

- Reliable and stable: With an average mean time between failures (MTBF) of ≥20,000 hours and minimal data fluctuation (≤±0.1%FS/year), it significantly reduces the need for frequent calibration and adjustment.

- User-friendly: Analog signals are plug-and-play, while digital signals support remote parameter configuration. Head-mounted models allow on-site reading without connecting to computers or control cabinets, facilitating inspection.

- High compatibility: Compatible with mainstream PLCs (Siemens, Mitsubishi, Rockwell) and DCS systems, eliminating the need for additional signal converters and reducing integration costs.

- Outstanding durability: Overload protection, vibration resistance, and corrosion-resistant design extend service life, maintaining stable performance even under harsh conditions and reducing replacement costs.

- Extruder: For manufacturing PE/PVC/PP pipes, plastic film blow molding, and rubber sealing strips, it monitors melt pressure in the die or barrel to control extrusion speed and product thickness.

- Injection molding machine: monitors barrel and nozzle pressure during injection molding to prevent defects like material shortage, flash, and shrinkage marks, ensuring precision of molded parts.

- Vulcanizing machine: Ensures uniform pressure control during the vulcanization process of rubber products, enhancing both strength and elasticity.

- Spinning machine: In the spinning process of polyester, nylon, spandex and other chemical fiber, the melt pressure of spinneret is monitored to control the uniformity of filament diameter and avoid the problems of broken filament and woolly filament.

- Polyester melt conveyance: Pressure monitoring of PET melt pipelines ensures stable delivery to spinning components.

- Pressure monitoring of molten metal pipelines (e.g., steel, aluminum, copper) and casting molds to prevent overflow or insufficient casting.

- Fire-resistant material molding: Pressure control of ceramic slurry and glass melt molding equipment ensures uniform product density.

- High-temperature food processing: Monitoring of pressure during the cooking and conveying of high-temperature melts such as chocolate, syrup, and jam to ensure production safety and product quality.

- Pharmaceutical excipient processing: pharmaceutical resin in high-temperature molten state, pressure control of suppository matrix, in compliance with GMP standards.

- Reaction vessel: Pressure monitoring system for high-temperature and high-pressure reaction vessels (e.g., in chemical synthesis or polymerization processes).

- High-temperature coatings/adhesives: Pressure control during molten state ensures uniform coating.

Product Introduction

High-temperature melt pressure sensors/transmitters are industrial measurement devices specifically engineered for high-temperature, high-pressure, high-viscosity, and corrosive media environments. They are primarily used to continuously monitor pressure parameters of melts (such as plastics, rubber, molten metals, and chemical fiber raw materials), providing critical data support for production process control, quality stability, and equipment safety. These devices are widely applied in industries including rubber and plastics, metallurgy, and chemical fiber manufacturing.

1. Core Features And Functions

1) Extreme condition adaptability (core feature)

2) Precise measurement and stable output

3) Structural and installation advantages

4) Additional features (available on select high-end models)

2. Core Industry Pain Points to Be Addressed

In high-temperature melt environments, conventional pressure sensors (e.g., strain gauge sensors or ceramic sensors) often exhibit issues like thermal instability, clogging susceptibility, accuracy drift, and short lifespan. This product specifically addresses these pain points:

3. Highlights of User Experience

4. Typical Use Cases

1)The rubber and plastic industry (core application field)

2) The chemical fiber industry

3) Metallurgical industry

4) Food and pharmaceutical industries

5) Other special scenarios

Summary

The core value of high-temperature melt pressure sensors/transmitters lies in their ability to deliver precise and stable measurements under extreme conditions. By addressing the challenges of monitoring high-temperature, high-pressure, and high-viscosity media, these devices not only ensure production safety but also enhance product consistency. They serve as critical equipment for achieving automated and intelligent production in industries such as rubber and plastics, chemical fibers, and metallurgy. Their flexible installation methods, strong compatibility, and long-lasting design further reduce overall operating costs and improve production efficiency for users.

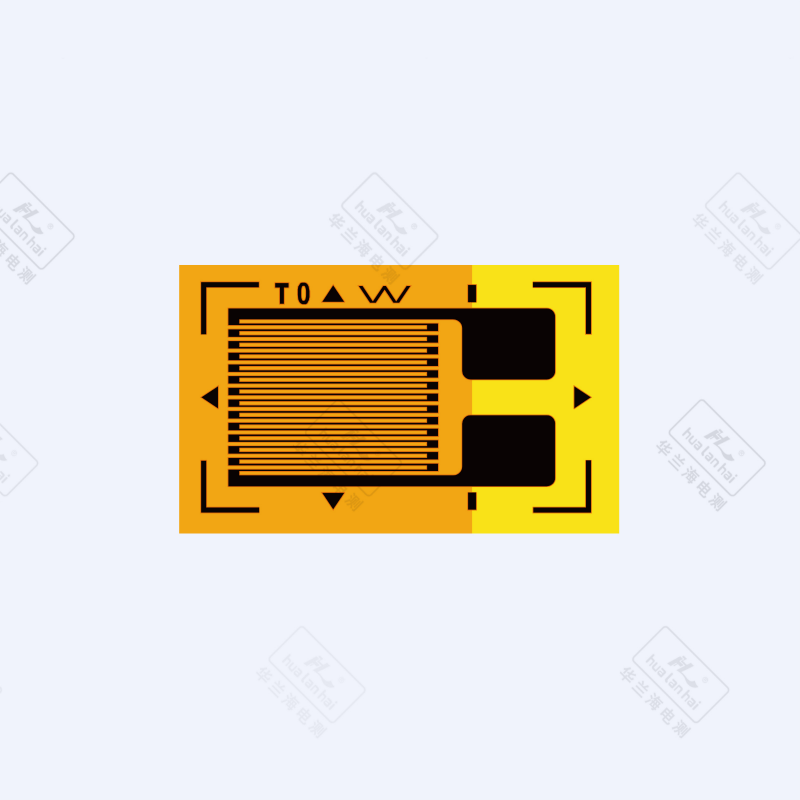

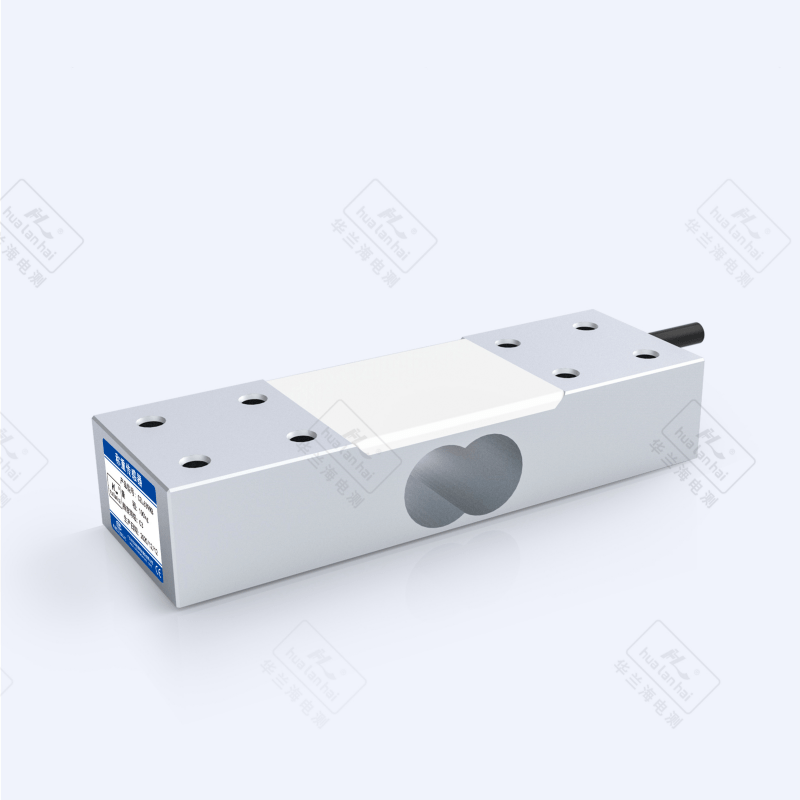

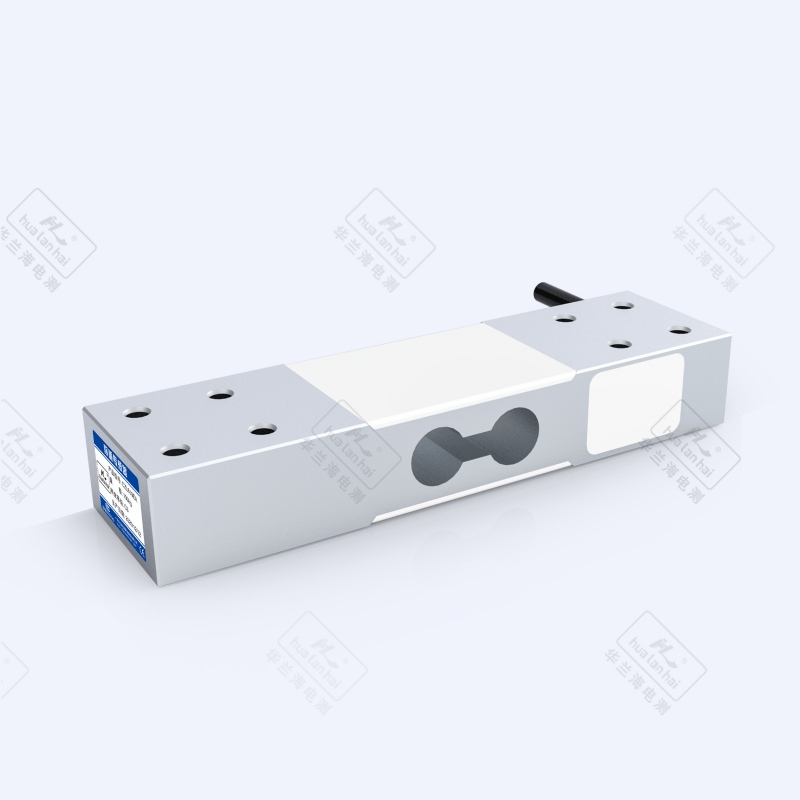

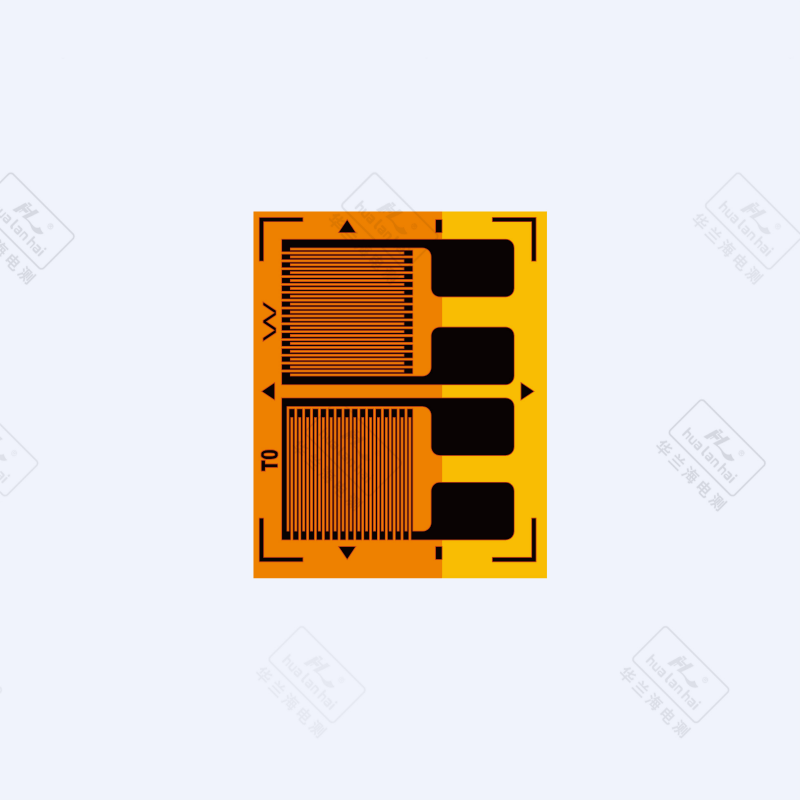

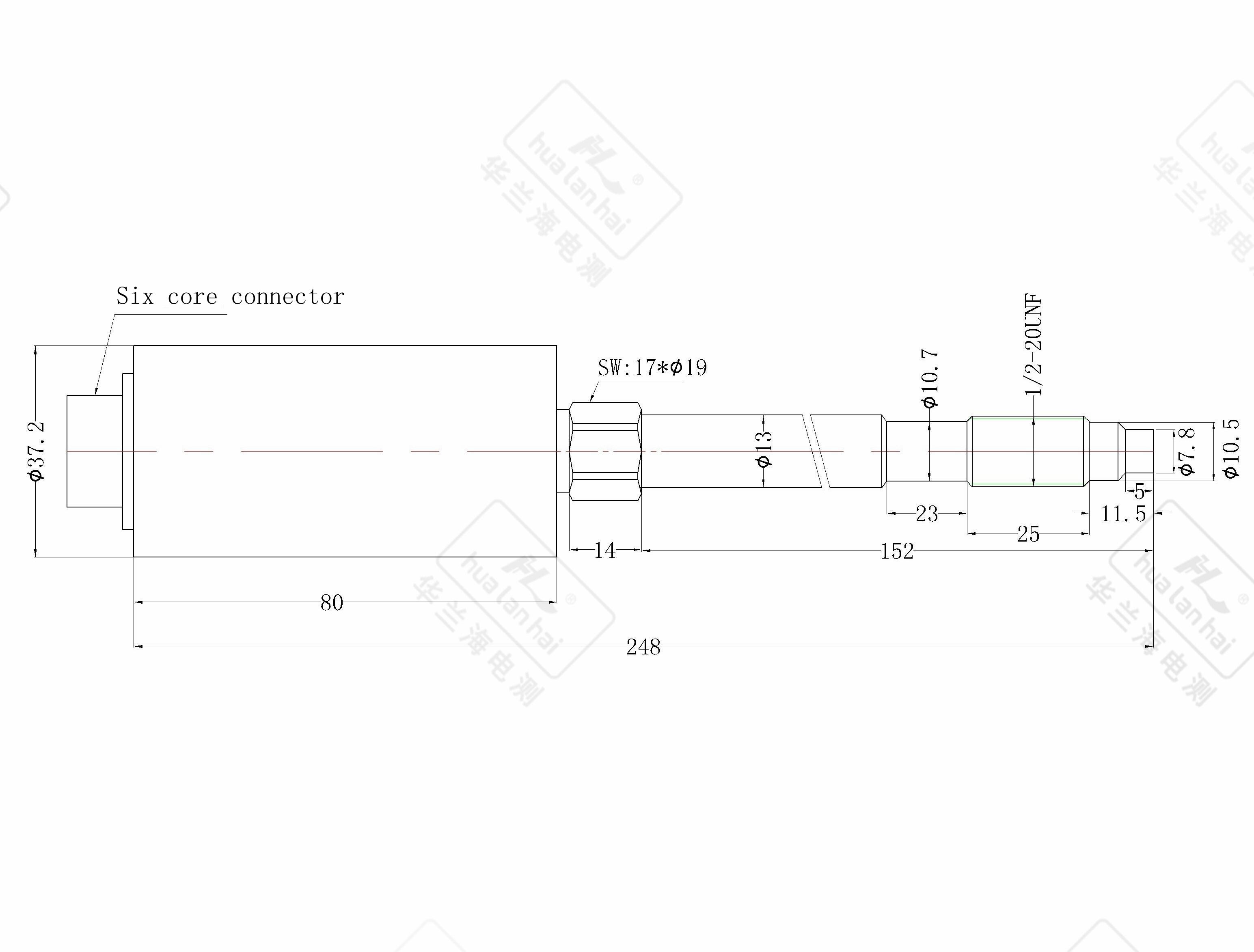

Detail Display

Parameters

| Parameter Name | Parameter Value |

| Pressure Range | 0-10MPa ~ 0-150MPa |

| Accuracy | 0.3% FS;0.5% FS;1.0% FS;1.5% FS |

| Output Signal | 2mV/V;3.3mV/V |

| Excitation Voltage | 10(6 ~ 12)VDC |

| Electric Connection | 6 Pins plug |

| Diaphragm Temp | 0 ~ 200-400℃ |

| Environment Temperature | -10℃ ~ 80℃ |

| Thermocouple Model | ------- |

| Thread Connection | M14×1.5;M22×1.5;M12×1.5;1/2-20UNF;Customize |