- Overview

- Recommended Products

Product Introduction

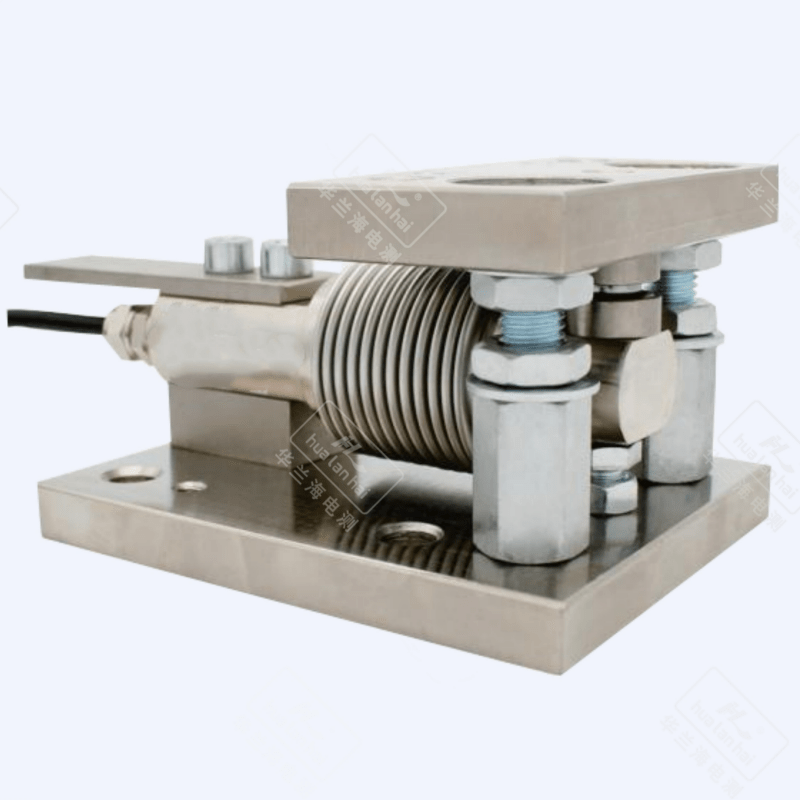

The weighing module is an integrated weighing solution that combines a weighing sensor, mounting connectors, a protective structure, and a signal conditioning unit. Through standardized design, it quickly adapts the sensor to industrial equipment. When subjected to force, the built-in sensor completes the force-to-electricity conversion, and after signal conditioning, it outputs a stable electrical signal. It combines advantages such as high integration, convenient installation, and strong stability, and is widely used in scenarios such as industrial storage tanks, reaction kettles, platform scales, and automated production lines that require rapid implementation of weighing functions. The following details are presented from the core dimensions to meet the needs of product selection, system integration, and solution implementation:

1. Product Features and Functions

Core Features

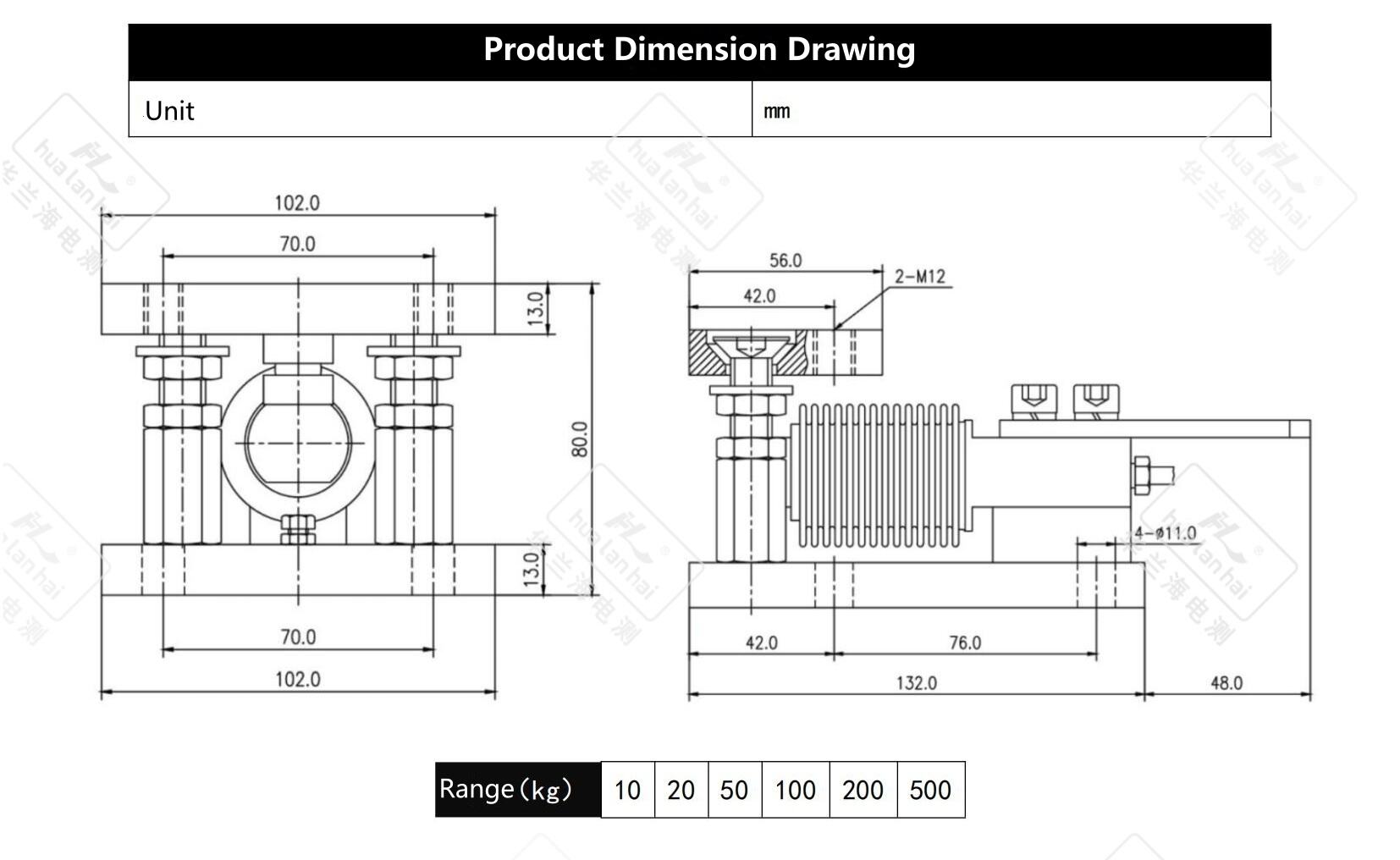

• Integrated Structure: Adopts an integrated design of "sensor + mounting base + junction box + protective shell", with some intelligent models integrating a signal transmitter, eliminating the need for additional accessories; the module weighs 5 - 50 kg, has a compact size (typically 100mm × 80mm × 150mm), and is suitable for the installation space of various devices.

• Precision and Stability: Built-in C3 - C2 grade weighing sensors, with non-linear error ≤ ±0.02%FS, repeatability error ≤ ±0.01%FS, and zero drift ≤ ±0.003%FS/℃; the module is pre-calibrated before leaving the factory, and can achieve the nominal accuracy without complex on-site debugging.

• Strong Environmental Adaptability: The sensor is made of alloy steel/304/316L stainless steel, the module's protection level reaches IP67 - IP68, and some explosion-proof models are certified by Ex d IIB T4/Ex ia IIC T6; it can adapt to a temperature range of -20℃ - 80℃, and resist dust, moisture, slight corrosion, and vibration impact.

• Wide Installation Compatibility: Provides three installation modes: fixed, floating, and semi-floating, suitable for the force characteristics of different devices such as storage tanks and platforms; the connection methods support bolt fastening and flange docking, are compatible with various specifications of mounting holes from M16 - M30, and can seamlessly connect with various industrial devices.

Core Functions

• Accurate Weight Measurement: Supports static/quasi-dynamic weighing, with a measuring range covering 50 kg - 100 t, and typical applications concentrated in the 1 t - 50 t range; the response time of the built-in sensor is ≤ 8 ms, which can meet the weight monitoring needs of scenarios such as intermittent feeding and continuous conveying.

• Standardized Signal Output: Provides analog signals (4 - 20 mA, 0 - 5 V, 0 - 10 V), digital signals (RS485/Modbus RTU, Profinet), and intelligent models support the HART protocol; it can directly connect to PLCs, DCSs, weighing instruments, and industrial IoT platforms without the need for additional signal converters.

• System-level Protection Function: Has overload protection (rated load 150% - 250%), short-circuit protection, and overvoltage protection functions; some models integrate a temperature compensation module to ensure stable measurement accuracy in a wide temperature environment; floating modules can automatically compensate for displacement errors caused by thermal expansion and contraction of the equipment.

• Multi-module Collaborative Control: Supports parallel networking of 2 - 8 modules, and achieves uniform load distribution through address coding; intelligent models have the function of data synchronization between modules, solving the problems of weight superposition and accuracy consistency in scenarios with distributed forces such as large storage tanks and platform scales.

2. Core Problems Solved

• Complex Sensor Integration Problem: Addressing the issue that traditional sensors need to be separately paired with mounting parts, junction boxes, and transmitters, the weighing module pre-integrates and pre-calibrates multiple components through an integrated design, and can be used on-site simply by fixing and wiring, reducing the installation and debuggingTime has been shortened from 1 - 2 days to 2 - 4 hours.

• Poor Equipment Adaptability: Different industrial equipment (storage tanks, reactors, platforms) vary greatly in installation dimensions and force - bearing methods. The weighing module provides multiple types of installation modes and connection specifications, enabling rapid integration of weighing functions without modifying the equipment's main structure, thus reducing equipment transformation costs.

• Accuracy Attenuation Under Complex Working Conditions: Vibration, temperature fluctuations, and material impact in industrial sites can easily cause accuracy drift of a single sensor. The weighing module controls measurement errors under complex working conditions within ±0.03%FS through integrated protective structures, temperature compensation, and anti - impact design, solving the accuracy problem in harsh environments.

• Coordination Errors Among Multiple Modules: When large - scale equipment uses multiple sensor groups for weighing, problems such as uneven load distribution and signal conflicts are likely to occur. The weighing module ensures that the error among multiple modules is ≤±0.01%FS through standardized networking protocols and automatic load distribution technology, improving the overall weighing accuracy of the system.

• High Operation and Maintenance Costs: When traditional sensors are installed dispersedly, fault troubleshooting and maintenance are difficult. The weighing module adopts a modular design, supporting independent replacement of a single module; the intelligent model comes with a fault diagnosis function, which can accurately locate problems such as overload, wire breakage, and signal abnormalities, reducing operation and maintenance costs.

3. User Experience

• Efficient and Convenient Installation: Standardized installation interfaces and positioning references, along with dedicated installation tools and gaskets, allow equipment maintenance personnel to complete installation without the need for professional weighing engineers; floating modules can automatically adjust the level without repeated calibration of the installation angle.

• Simplified Commissioning Process: The module has completed sensor calibration and signal commissioning before leaving the factory, and on - site only requires zero - point calibration and range calibration (process ≤15 minutes); the intelligent model supports remote calibration via mobile APP or host computer without on - site operation.

• Worry - free Operation and Maintenance: The fully sealed protective structure reduces dust and moisture intrusion, with an annual average failure rate ≤0.3%; the junction box is integrated inside the module, avoiding the risk of failure caused by messy cables; in case of a fault, the problem module can be quickly located through indicator lights or software, and the system does not need to be recalibrated after replacement.

• Reliable Data Feedback: Static weighing data fluctuation ≤±0.005%FS, with no obvious lag in quasi - dynamic scenarios; the intelligent module can upload weight data and its own operating status in real - time, facilitating remote monitoring by management personnel and improving the transparency of the production process.

• High Flexibility in Expansion: The same weighing system can expand the range by increasing the number of modules without replacing the core equipment; it supports docking with existing production management systems, and the data can be directly used for inventory management and production report generation, improving data utilization.

4. Typical Application Scenarios

1) Weighing of Industrial Storage Tanks and Reactors

• Chemical raw material storage tanks: Weighing of 10 - 50t chemical raw material storage tanks, using a combination of 3 - 4 "fixed + floating + semi - floating" modules for installation, automatically compensating for temperature difference displacement of the tank and material off - load, with IP68 protection suitable for the humid environment of the workshop, and accuracy of ±0.02%FS ensuring accurate inventory measurement.

• Pharmaceutical reactors: Weighing of 1 - 10t pharmaceutical reactors, using 316L stainless steel modules, complying with GMP standards, and explosion - proof models suitable for flammable and explosive reaction environments, for real - time monitoring of feeding weight and material changes during the reaction process, and cooperating with the DCS system to achieve precise material control.

2) Transformation of Platform Scales and Truck Scales

• Workshop platform scales: 5 - 20t workshop turnover platform scales, with 4 fixed modules installed at the four corners of the scale body, directly replacing old sensors, installation cycle≤4 hours, ready for use after calibration, with anti-shock design to handle the impact of workpiece hoisting.

• Upgrade of old weighbridges: For 50-100t old weighbridges, 8 heavy-duty modules are used to replace the original sensing system. The modules come with built-in signal conditioning function, are compatible with the original weighing instrument, and the upgrade cost is only 1/3 of a new weighbridge, with accuracy restored to C3 level.

3)Weighing in Automated Production Lines

• Ingredient batching production line: In the food and feed industries, 2-4 modules are installed at the bottom of the ingredient bin to provide real-time feedback on material weight, and are linked with the PLC control system to achieve automatic feeding, with an accuracy of ±0.01%FS to ensure accurate ingredient proportions.

• Finished product sorting line: In the automotive parts and home appliance industries, modules are embedded in the sorting platform to detect product weight in real-time and distinguish between qualified/ unqualified products, with a response time of ≤8ms to adapt to high-speed sorting rhythm (≤10 pieces/minute).

4) Special Industrial Scenarios

• Explosion-proof scenario: Explosion-proof weighing equipment in the coal mine and oil and gas industries uses Ex d IIB T4 explosion-proof modules, installed on the explosion-proof weighing platform to meet the safety requirements of explosive environments and support connection with the coal mine safety monitoring system.

• Corrosion scenario: For pickling tank weighing in the electroplating and metallurgy industries, 316L stainless steel + PTFE coated modules are used, which are resistant to strong acid and alkali corrosion, with IP68 protection to withstand spray cleaning, suitable for electroplating solution weight monitoring and composition control.

5.Usage Instructions (Practical Guide)

1) Installation Process

• Preparation: Clean the equipment installation surface (ensure it is flat and burr-free, with a flatness error of ≤0.1mm/m), determine the number of modules based on the equipment weight and size (usually ≥3), and plan the combination scheme of "fixed + floating + semi-floating" (e.g., for 3 modules: 1 fixed + 1 floating + 1 semi-floating).

• Module Fixing: Secure the fixed module to the ground foundation with bolts, lightly fix the floating and semi-floating modules (leaving 5-10mm displacement space), and ensure that the top of the module is tightly attached to the equipment support leg with no gaps.

• Wiring and Networking: Connect the signal wires of each module to the main junction box (intelligent modules are directly connected in parallel), and wire according to the specification of "red - power +, black - power -, green - signal +, white - signal -"; digital modules need to be set with a unique address through software to avoid signal conflicts.

• Protection Treatment: For outdoor installation, add a rain and sun protection cover to the module; in a corrosive environment, apply anti-corrosion coating to the non-loaded surface of the module, seal the wiring with a waterproof junction box, and mark it properly.

2) Calibration and Debugging

• Zero Calibration: Turn on the power and preheat for 30 minutes, ensure the equipment is unloaded, execute the "zero calibration" command to make the system zero output within ±0.002%FS. If the deviation is too large, check whether the module installation is tight and whether there are any foreign objects blocking.

• Range Calibration: Use standard weights or force sources for loading (loading weight ≥50% of the rated load), record the deviation between the system display value and the standard value, and correct the linear error through the weighing instrument or software to ensure the error ≤C3 level allowable value (±0.02%FS).

• Eccentric Load Test: Place weights of the same weight at different positions on the equipment, observe the consistency of the system readings, and the deviation should be ≤±0.02%FS. If the deviation is too large, adjust the displacement space of the floating module to ensure uniform load distribution.

3) Routine Maintenance

• Regular Inspection: Clean the dust and oil on the module surface monthly, and check the tightness of the installation bolts (pay special attention to the fixed module);Check whether the wiring is loose and the protective structure is intact every quarter, and perform a zero-point calibration.

• Fault handling: If there is data drift, first check the power supply voltage (stable at 12-24V DC) and ambient temperature; if the reading is abnormal, use the module's built-in fault indicator light or software to troubleshoot the problem module. When replacing, select products of the same model and batch, and only perform zero-point calibration again after replacement.

6. Selection method (precise matching requirements)

1) Core parameter determination

• Range selection: The range of a single module is selected by dividing 1.2-1 times the total weight of the equipment by the number of modules (such as 4 modules for 50t equipment, 15-19t for a single module range), with reserved impact load and safety margin.

• Accuracy level: For industrial metrology, choose modules with built-in C3 level sensors, for laboratory or pharmaceutical industry, choose C2 level, and for general monitoring scenarios, choose C6 level; for dynamic weighing, ensure that the module response time is ≤ 8ms.

• Signal type: For traditional control systems, choose analog signal modules, for smart factories or IoT scenarios, choose RS485/Profinet digital modules, which need to match the Communication Protocol of existing PLC/instruments.

2) Environmental adaptability selection

• Temperature: For regular scenarios (-20 ℃~ 60 ℃), choose ordinary modules; for high temperature scenarios (60 ℃~ 120 ℃), choose high temperature compensation type; for low temperature scenarios (-40 ℃~ -20 ℃), choose low temperature resistant modules.

• Medium: For dry environments, choose alloy steel modules; for humid/food industries, choose 304 stainless steel; for strong corrosive environments (acid-base solutions), choose 316L stainless steel or Hastelloy modules.

• Protection and explosion-proof: For indoor dry environments, ≥ IP67; for outdoor/humid environments, ≥ IP68; for explosion-proof scenarios, choose corresponding explosion-proof level modules according to the region (such as choosing Ex ia IIC T6 for chemical workshops).

3) Installation and system compatibility

• Installation mode: For fixed equipment, choose the "1 fixed + multiple floating" combination, and for mobile platforms, choose the fully fixed type. When the equipment has thermal expansion and contraction, the number of floating modules should not be less than 1/3 of the total number.

• Compatibility: Confirm that the module installation hole specification matches the equipment support leg, and the signal output is compatible with the existing control system. When networking multiple modules, choose modules of the same brand that support a unified protocol to reduce integration difficulty.

4) Additional requirement confirmation

• Certification requirements: For measurement scenarios, the built-in sensors of the module need to have CMC certification, for the food and pharmaceutical industry, GMP/FDA certification is required, and for export products, OIML/NTEP certification is required. Special features: For remote monitoring, choose an intelligent model with NB-IoT/LoRa wireless module. For high-speed dynamic weighing, choose a module with a response time of ≤ 5ms. For large-sized equipment, choose a module with horizontal adjustment function.

Summary

The weighing module has the core advantages of "integrated design, convenient installation, and high stability", which solves problems such as cumbersome sensor integration, difficult equipment adaptation, and poor accuracy in complex environments in industrial weighing scenarios. User Experience focuses on efficient installation, worry-free operation and maintenance, and flexible expansion. When selecting, it is necessary to prioritize equipment weight, installation environment, accuracy requirements, and system compatibility, and then make decisions based on module type and additional functions. During use, fixed and floating modules should be reasonably matched, and installation specifications and regular calibration requirements should be strictly followed to ensure the long-term stable operation of the system. It is suitable for industrial material tanks, platform scales, automated production lines and other fields, and is the preferred solution for quickly realizing equipment weighing functions, especially for efficient implementation of old equipment upgrades and new projects.

Detail Display