- Overview

- Recommended Products

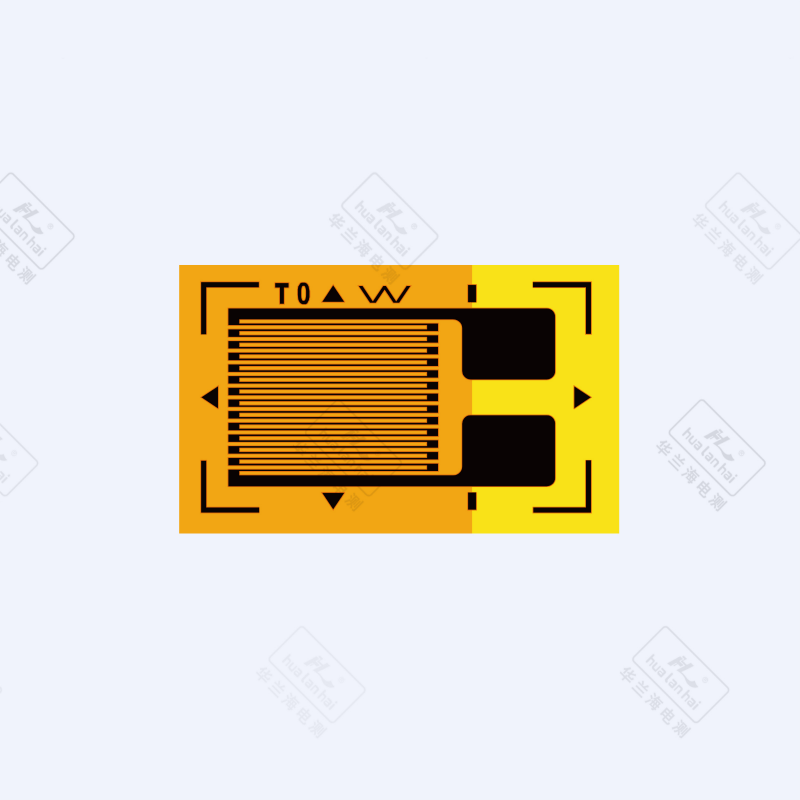

- High Precision & Sensitivity: Utilizing precision metal strain gauges (e.g., Kevlar, Kama alloy) or semiconductor strain gauges, these components feature stable strain coefficients with measurement accuracy of ±0.01%FS to ±0.1%FS. They can accurately detect minute mechanical deformations (detecting micro-strain levels) and are ideal for precision measurement applications.

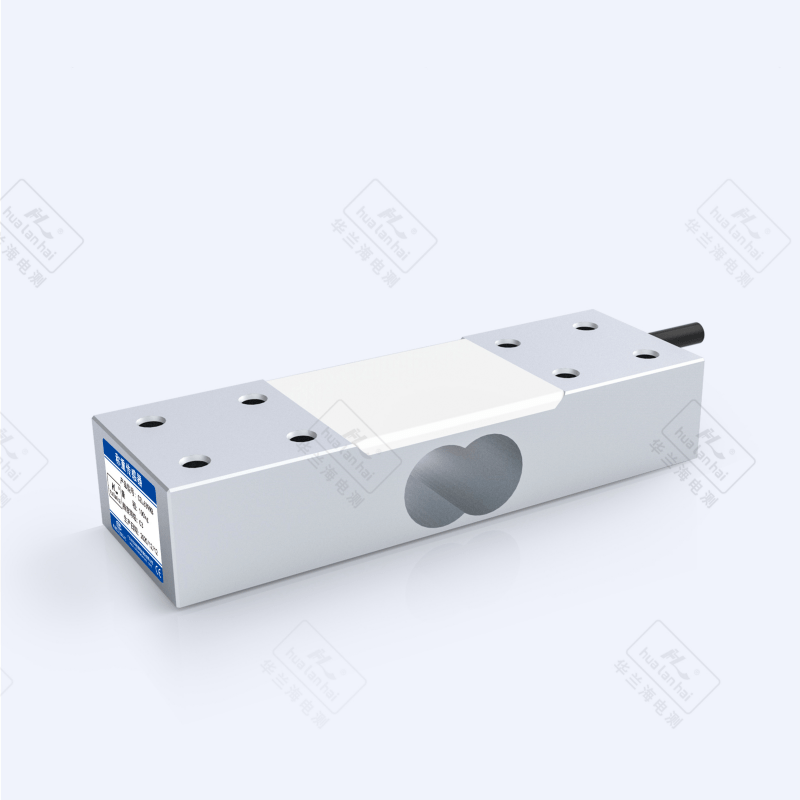

- Wide-range adaptability: By optimizing strain gauge bonding techniques and selecting various elastic sensing elements (e.g., beam, column, or ring types), the system achieves measurement ranges from grams to hundreds of tons. This capability meets both small-scale requirements for electronic scales and large-scale monitoring needs in industrial presses.

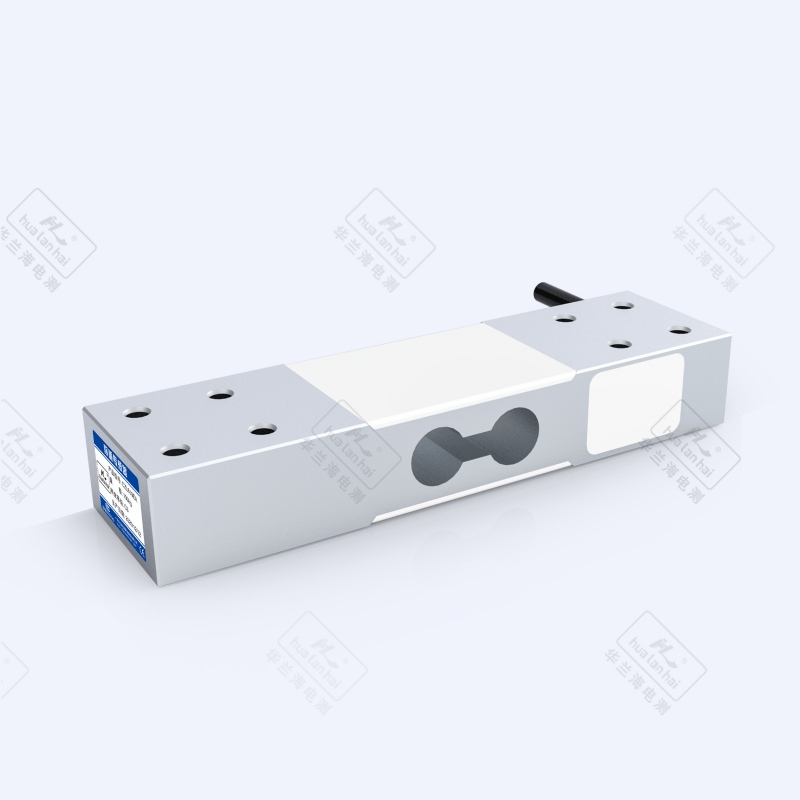

- Good stability and repeatability: The elastic sensitive element is treated by aging to reduce the drift caused by stress relaxation; the strain gauge is used by high temperature aging and sealing protection process to ensure the resistance value is stable in long-term use, the repeatability error is less than ±0.05%FS, and the data consistency is guaranteed.

- Mechanical-to-electrical signal conversion: This process transforms physical quantities like external forces and pressures into precise resistance signals with excellent linearity. When combined with subsequent conditioning circuits, it generates standard industrial outputs such as 4-20mA and 0-10V, enabling direct integration with measurement and control systems for digital monitoring of mechanical parameters.

- Temperature compensation feature: The system incorporates built-in temperature-compensated strain gauges or utilizes a dedicated compensation circuit to counteract environmental temperature fluctuations (-20℃ to 80℃, the standard operating range). This mechanism prevents measurement errors caused by temperature drift, ensuring stable performance across the entire temperature spectrum.

- Anti-interference and protection capability: The strain gauge is insulated and encapsulated, with the elastic body surface treated with anti-corrosion methods (e.g., galvanizing or powder coating) to resist humidity and dust in typical industrial environments. Some high-end models feature built-in electromagnetic shielding layers to minimize interference from power grids and electromagnetic devices.

- Compact and Lightweight Design: The elastic-sensitive element features a compact structure, with the entire mechanism measuring just a few cubic centimeters in volume and being lightweight. This makes it ideal for integration into various small-scale sensor products, such as smart wearables and miniature pressure sensors.

- Modular design: Some components feature standardized interfaces (e.g., threaded fastening and pin connections), enabling rapid assembly with various housings and conditioning circuits, thereby reducing R&D and assembly costs for sensor manufacturers.

- Overload protection design: The elastic sensitive element is made of fatigue-resistant material, with an overload capacity of 120%~200%FS. It is resistant to permanent deformation under instantaneous impact force, thus extending the service life of the movement.

- Precision measurement solution: To address the low accuracy and high reading error of traditional mechanical sensing components (e.g., spring-based or lever-based), this technology meets stringent data precision requirements in industrial applications like material batching and metrological verification, ensuring reliable measurement outcomes.

- Range adaptation limitation: This addresses the issue where a single mechanism cannot meet multi-range requirements. Through structural designs of different elastomers, it enables measurement adaptation from minimal force (e.g., medical infusion pressure) to extreme force (e.g., bridge weighing) within the same technical framework, thereby reducing scenario-switching costs.

- Environmental interference issues: The system addresses measurement drift caused by temperature, humidity, and vibration by employing temperature compensation and sealing technologies, ensuring stable operation in challenging environments including high/low-temperature workshops, humid warehouses, and vibrating machinery (e.g., machine tools).

- R&D efficiency challenges for sensor manufacturers: To address the prolonged development cycles and high costs of core components, modularized mechanisms enable direct integration, reducing material selection and strain gauge application investments while accelerating product commercialization.

- Long-term stability: Addresses the short lifespan of traditional movements due to fatigue and aging. The fatigue-resistant elastic materials and precision manufacturing ensure a Mean Time Between Failures (MTBF) of ≥50,000 hours, reducing maintenance costs associated with frequent sensor replacements.

- Easy integration: Featuring standardized structural design and interfaces, it can be assembled with sensor housings and circuit modules without complex modifications, compatible with automated production lines. Assembly time is reduced to under 10 minutes, significantly boosting production efficiency.

- Debugging friendliness: The resistance output exhibits excellent linearity, eliminating the need for complex algorithm adjustments during debugging. Simple zero-point and range calibration can meet operational requirements, significantly reducing technical personnels operational complexity.

- Durability: With long-term use, the data drift remains ≤±0.1%FS/years, eliminating frequent recalibration and reducing maintenance workload. This makes it ideal for remote monitoring scenarios without human supervision, such as pipeline pressure monitoring.

- Cost control: Core materials (strain gauges, elastomers) are mature and readily available, with standardized production processes. Compared to piezoelectric or capacitive mechanisms, this reduces costs by 30% to 50%, while the extended lifespan further lowers lifecycle costs.

- Scenario compatibility: The output signal can be converted to industrial standard formats like 4-20mA or RS485 through a simple conditioning circuit, enabling seamless integration with mainstream PLC and DCS systems without requiring additional signal converters.

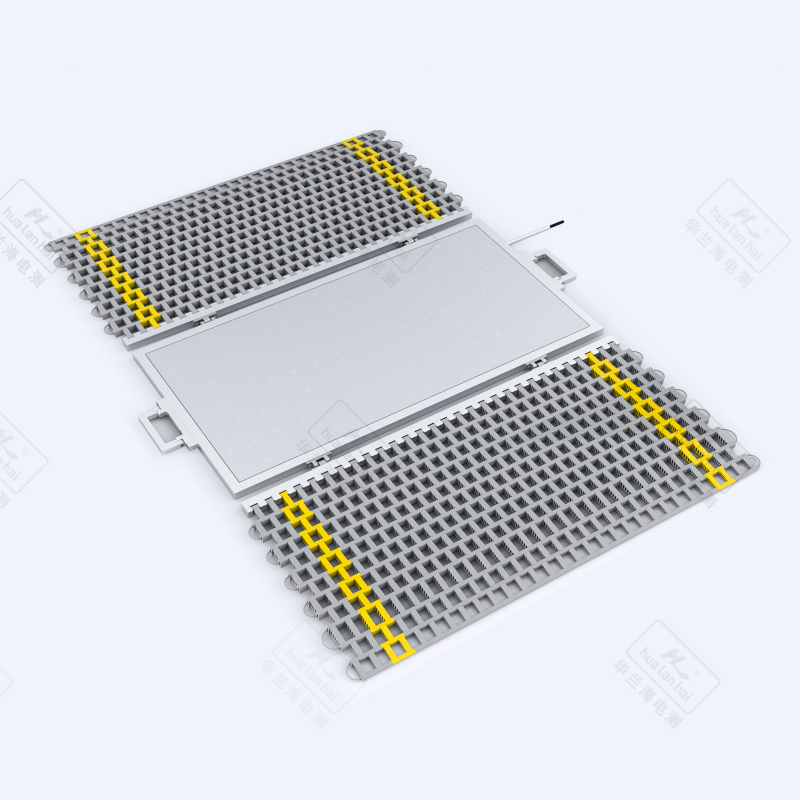

- Electronic Weighing Equipment: As the core component of electronic platform scales, floor scales, and overhead scales, it delivers precise weight measurement for goods. Widely used in warehouses, logistics parks, and ports, its accuracy meets trade settlement standards.

- The ingredient system monitors the weight of the material bin or the amount of material input in the automatic ingredient equipment of chemical industry and food processing, and cooperates with the control system to achieve accurate ingredient mixing, avoiding the waste of raw materials or the error of proportion.

- Structural stress monitoring: This technology is applied to large-scale structures including bridges, buildings, and wind turbine blades. It captures real-time mechanical signals from structural deformation, providing critical data for structural safety assessments.

- Load monitoring: Installed on the machine tool spindle, robot joints, crane hooks, etc., to monitor load variations during operation and prevent equipment damage caused by overload.

- Industrial pressure sensors: As the core components in hydraulic and pneumatic systems, they monitor pipeline and cylinder pressures to ensure stable system operation, such as in injection molding machine hydraulic systems.

- Medical force sensing devices: These systems monitor surgical and rehabilitation forces in robotic-assisted procedures to ensure precision and safety, such as force feedback control in orthopedic surgeries.

- Vehicle weighing: Used in dynamic weighing systems (e.g., highway overload control stations) and truck scales to monitor total vehicle weight and axle load, preventing road damage caused by overloading.

- Express sorting equipment: In automated sorting lines, it sorts parcels by weight through real-time monitoring, boosting sorting efficiency.

- Smart wearables: These devices, such as fitness trackers and health scales, monitor body weight and exercise force to support health data analytics.

- Smart home devices: For example, grip force sensors in smart door locks and collision detection in robotic vacuum cleaners, these technologies enhance the intelligent interaction experience of devices.

Product Introduction

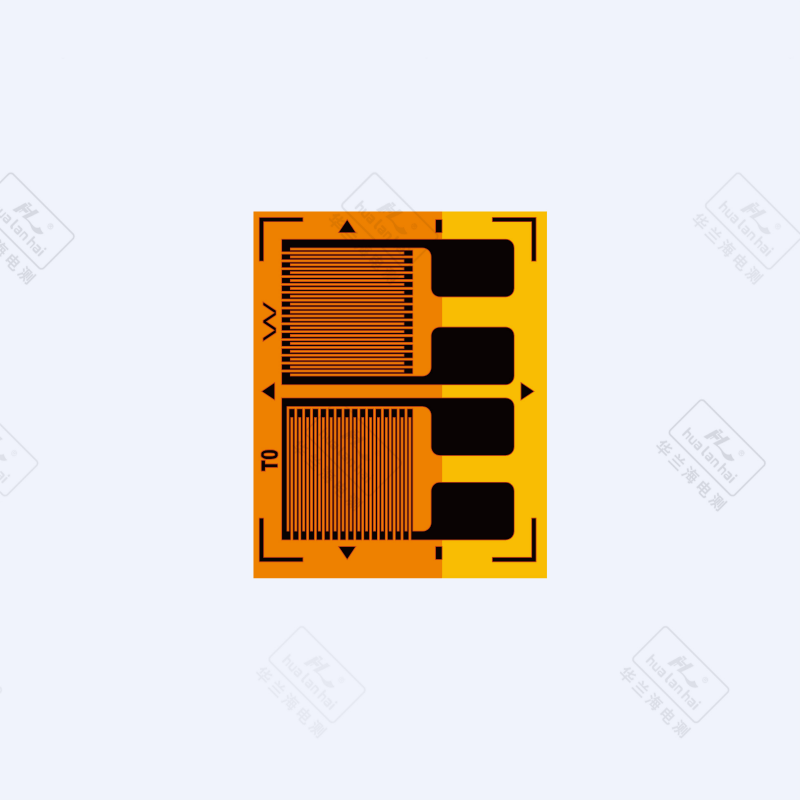

The strain gauge sensor core is the essential functional component of strain gauge sensors. Its fundamental principle utilizes the "strain effect" of metal or semiconductor materials—where the resistance value changes systematically when materials deform under force. By converting this resistance change into measurable electrical signals, it enables precise detection of mechanical quantities such as force, pressure, weight, and torque. As the "heart" of the sensor, it directly determines its measurement performance and is widely applied in industrial measurement and control, weighing systems, transportation logistics, medical equipment, and other fields.

1. Core Features and Functions

1) Core Performance Advantages

2) Core Functional Performance

3) Structure And Integration Features

2. Core Industry Pain Points to Be Resolved

In mechanical measurement scenarios, traditional sensor mechanisms often face challenges such as measurement inaccuracies, poor adaptability, short lifespan, and integration difficulties. The strain gauge sensor mechanism specifically addresses these core pain points:

3. Highlights of User Experience

4. Typical Use Cases

1) Industrial weighing and measurement

2) The field of mechanical quantity monitoring and control

3) Pressure and force sensing

4) Transportation and logistics sector

5) Consumer electronics and smart devices

Summary

Strain gauge sensor cores, distinguished by their "high precision, wide measurement range, and cost-effectiveness," have become the backbone of sensor products by addressing challenges in mechanical measurement accuracy, stability, and integration. With a mature technical framework, user-friendly operation, and broad applicability, they hold an irreplaceable position across industries including manufacturing, healthcare, transportation, and consumer electronics, providing reliable sensing support for automated measurement and control systems.

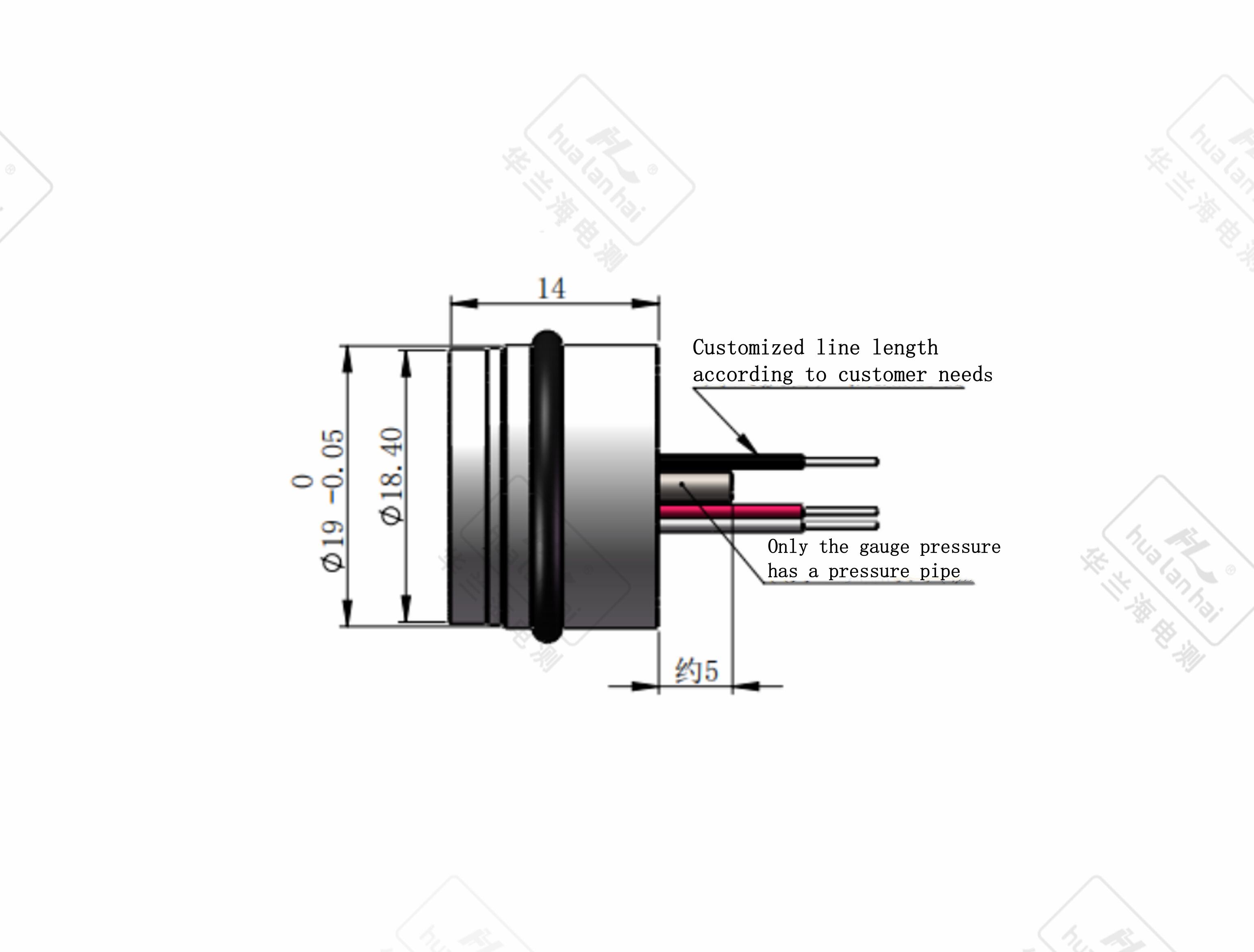

Detail Display

Parameters

| Parameter Name | Parameter Value |

| Range | 35KPa~10MPa |

| Input | ≤2mA DC |

| Output | 1.5mA DC 35℃ |

| Zero point output | ±2mV DC |

| Full range output | ≥60mA DC |

| Temperature zero drift | ±1% FS |

| Temperature sensitivity drift | ±1% FS |

| Nonlinear | ±0.25% FS |

| Lagging | ±0.75% FS |

| Repeatability | ±0.75% FS |

| Compensation temperature | 0℃~70℃ |

| working temperature | -40℃~125℃ |

| Product size | φ 19x14 |