- Overview

- Recommended Products

Product Introduction

The spoke-type load cell is a force-sensitive detection element based on the principle of strain resistance, with a spoke-shaped elastomer as its core structure. When subjected to force, the deformation of the elastomer drives the strain gauge to produce a change in resistance, which is then converted into a measurable electrical signal. It combines advantages such as compact structure and outstanding anti-eccentric load capacity, and is widely used in weighing scenarios with medium to low loads and limited space. The following provides a detailed explanation from the core dimensions to meet the needs of product selection, technical evaluation, and solution writing:

1. Product Features and Functions

Core Features

• Structural Design: Adopts a spoke-type integrated structure (the rim and hub are connected by spokes, with a height typically ranging from 20 to 80 mm), featuring uniform rigidity distribution, excellent resistance to eccentric load/lateral force (capable of withstanding an eccentric load force of ±15% - ±20% of the rated load), effectively dispersing the impact of non-axial loads, and strong force-bearing stability.

• Precision Performance: Precision levels cover C2 - C6, with mainstream models reaching C3. Nonlinear error ≤ ±0.02%FS, repeatability error ≤ ±0.01%FS, zero drift controlled within ≤ ±0.003%FS/°C, and good precision retention in dynamic intermittent load scenarios.

• Materials and Protection: The elastomer commonly uses alloy steel (yield strength ≥ 900 MPa) or 304/316L stainless steel, with the surface passivated or nickel-plated to enhance corrosion resistance; the protection level is typically IP66/IP67, and special customized models can reach IP68, suitable for humid and dusty industrial environments.

• Installation Compatibility: The upper and lower end faces use bolt fixing or flange connection, with some models supporting thread adaptation, low installation height (minimum up to 18 mm), suitable for narrow spaces mainly subject to vertical forces, and can be used independently or in multiple combinations.

Core Functions

• Weight/Force Value Detection: Supports static weighing and quasi-dynamic weighing (response time ≤ 8 ms), with a measurement range covering 0.1 t - 200 t, and typical applications concentrated in the 1 t - 50 t range. Some customized models can meet special requirements above 200 t.

• Signal Output: Provides standard analog signals (4 - 20 mA, 0 - 5 V, 0 - 10 V) and digital signals (RS485/Modbus RTU), with some intelligent models supporting the CANopen protocol, enabling direct connection to PLC, DCS, and weighing management systems.

• Additional Functions: Integrates wide temperature range temperature compensation (-30°C - 80°C), has overload protection (150% - 250% of the rated load), explosion-proof models are certified by Ex d IIB T4 Ga/Ex ia IIC T6 Ga, and some models feature built-in cable anti-pull design.

• Long-Term Reliability: Fatigue life ≥ 10⁷ cycles of load, excellent continuous operation stability under rated load, annual drift ≤ ±0.015%FS, suitable for long-term continuous operation in industrial scenarios.

2. Core Problems Solved

• Inaccurate Measurement Under Eccentric Load Conditions: To address the issue of excessive error in traditional sensors under non-axial loads, through the optimization of force transmission in the spoke-type structure, the eccentric load error is controlled within ±0.03%FS, thus resolving the accuracy issues in scenarios such as silo eccentricity and material impact.

• Difficult Installation in Confined Spaces: By virtue of its "short and thick" structural characteristics (diameter 50 - 200mm, height 20 - 80mm), it solves the installation adaptation problems in space-constrained scenarios such as inside equipment, small weighing instruments, and embedded weighing modules, without the need for additional redundant space.

• Prone to Damage Under Vibration and Impact: The stress distribution of the spoke-type elastomer is more uniform, and its impact resistance is improved by over 30% compared to column-type sensors, effectively avoiding permanent deformation of the sensor in scenarios such as mechanical vibration and material drop impact, and extending its service life.

• Insufficient Adaptability to Multiple Scenarios: Through material upgrade (e.g., 316L stainless steel) and enhanced protection (IP68), it solves the corrosion problem of sensors in humid and corrosive environments such as food processing and chemical batching, while the explosion-proof model meets the safety requirements of flammable and explosive scenarios.

• Cumbersome System Integration and Docking: It supports multiple types of signal output and mainstream industrial protocols, solves the compatibility problems with different brands of PLCs (e.g., Mitsubishi, Schneider) and weighing instruments, and reduces the investment in intermediate equipment such as signal converters.

3. User Experience

• Installation Convenience: Standardized end-face mounting holes and positioning reference surfaces, with dedicated mounting gaskets and fastening bolts, enable horizontal positioning to be completed without the need for professional calibration tools, and a single person can complete the installation and commissioning of a single sensor within 30 minutes.

• Operation and calibration: It supports one-key zeroing and two-point calibration on the instrument, simplifies the calibration process (only requires standard weights of 20% and 100% of the rated load), and the digital model can achieve remote calibration and parameter configuration through the host computer software, reducing the operation threshold.

• Low maintenance Cost: The fully sealed structure reduces the intrusion of dust and moisture, with an annual average failure rate ≤0.3%; the terminal block adopts an anti-loosening design, and the cable interface has waterproof and dustproof sealing, requiring only quarterly cleaning and zero-point inspection in daily use, with low maintenance workload.

• Data Feedback: The static weighing data fluctuation ≤±0.005%FS, with no obvious lag in quasi-dynamic scenarios; the digital model has a built-in fault diagnosis module that can provide real-time feedback on overload, disconnection, abnormal temperature and other states, facilitating quick problem location.

• Compatibility Experience: It is compatible with over 95% of weighing control devices on the market, supports automatic load distribution when multiple sensors are used in parallel, without the need for additional equalizers; the intelligent model can be directly connected to the industrial Internet of Things platform to achieve remote data monitoring.

4. Typical Application Scenarios

1) Industrial Weighing Equipment Manufacturing

• Small and Medium-sized Platform Scales/Floor Scales: Core sensing units for 1-50t platform scales and floor scales, with a compact structure suitable for internal installation in weighing equipment, and anti-eccentric load characteristics ensuring accuracy consistency at different weighing positions (e.g., supermarket pricing platform scales, workshop turnover floor scales).

• Customized Weighing Equipment: Used for explosion-proof electronic scales and corrosion-resistant chemical scales, 316L material + explosion-proof certification can meet the needs of special industries, and the spoke structure can adapt to the diversified structural design of weighing equipment.

2) Engineering and Construction Machinery

• Weighing of Loaders/Shovels: Installed in the hydraulic system of the bucket, indirectly weighing by detecting hydraulic pressure, the spoke-type structure has strong anti-vibration and impact capabilities, adapts to the harsh operating environment of construction machinery, and the accuracy can reach ±0.5%FS.

• Pressure Monitoring of Hydraulic Supports: Monitoring the working resistance of hydraulic supports in coal mines, using explosion-proof spoke-type sensors with a protection level of IP67, capable of long-term stable operation in dusty and humid environments, providing data support for the safety of supports.

3) Industrial Process Control

• Weighing of Small and Medium-sized Material Tanks/Silos: Weighing of batching tanks and buffer silos in the pharmaceutical and food industries, with 4 sensors symmetrically installed, anti-eccentric load characteristics solve the problem of center of gravity shift of the material tank, and cooperate with the control system to achieve accurate feeding.

• Weighing of Packaging Machinery: Dynamic weighing modules for particle packaging machines and liquid filling machines, with a response time ≤8ms to meet high-speed packaging requirements, and accuracy controlled within ±0.1%FS to ensure compliance with packaging metrology.

4) Material Testing and Scientific Research Equipment

• Tensile/Compression Testing Machines: Static force value measurement in material mechanics testing, C2-level accuracy can meet the needs of scientific research-level testing, and the spoke structure is evenly stressed, ensuring the repeatability and accuracy of test data.

• Fatigue Testing Equipment: Load monitoring in the fatigue life testing of components, with a cycle life ≥10⁷ times and stable mechanical properties, can meet the needs of long-term testing experiments.

5) Special Industry Applications

• Food and Pharmaceutical Industries: Hygienic-grade 316L stainless steel sensors, with surface polishing treatment (Ra ≤ 0.8μm), comply with GMP standards, used in raw material weighing, finished product metering and other processes, facilitating cleaning and disinfection.

• Mining and Metallurgy: High-temperature spoke-type sensors (compensation temperature -40°C~120°C), used for ore sorting equipment and weighing of metallurgical furnace hoppers, can adapt to the use requirements of high-temperature and dusty environments.

5. Usage Instructions (Practical Guide)

1) Installation Process

• Preparation: Clean the installation surface (ensure it is flat and burr-free, with a flatness error ≤0.05mm/m), inspect the appearance of the sensor (the elastomer is free of deformation and the cable is undamaged), and verify the compatibility of the installation bolt specifications with the sensor.

• Positioning and Fixing: Place the sensor vertically on the mounting base to ensure that the load is transmitted axially, use a torque wrench to tighten it according to the specified torque (15-40N·m is recommended for alloy steel sensors, 10-30N·m for stainless steel), and avoid over-tightening to prevent damage to the elastomer.

• Wiring Specifications: For analog signals, follow the wiring principle of "red - power +, black - power -, green - signal +, white - signal -"; for digital signals, connect the corresponding pins according to the Modbus protocol; the wiring should be away from strong electromagnetic interference sources (such as frequency converters and high-voltage cables), with a distance ≥15cm.

• Protection Treatment: When installing in outdoor or humid environments, use waterproof junction boxes to seal the cable joints, and dust covers can be installed on the exposed parts of the sensor; in corrosive environments, apply a special anti-corrosion coating on the non-stressed surface.

2) Calibration and Debugging

• Zero Calibration: Turn on the power and preheat for 20 minutes, execute the "zero calibration" command through the weighing instrument or host computer to ensure that the zero output is within ±0.002%FS, and if the deviation is too large, check the installation levelness.

• Load Calibration: Place standard weights of 20% and 100% of the rated load in sequence, record the output signal values of the sensor, correct the linear error through calibration software, and ensure that the error at each load point ≤ the allowable value of the corresponding accuracy class (e.g., ≤±0.02%FS for C3 class).

• Dynamic Debugging: In a quasi-dynamic scenario, adjust the instrument filtering parameters (filtering frequency 8-15Hz), test the sensor's response speed and data stability, and avoid signal fluctuations caused by material impact.

3) Routine Maintenance

• Regular Inspection: Clean the dust and oil on the sensor surface monthly, check the tightness of the wiring terminals; perform zero calibration once every six months, and complete full-scale calibration and performance testing once a year.

• Fault Handling: If data drift occurs, first check the power supply voltage (stable at 10-30V DC) and the flatness of the installation surface; if the signal is abnormal, check whether the cable is damaged or the strain gauge is overloaded and damaged, and replace the sensor if necessary.

6. Selection Method (Precisely Matching Requirements)

1) Determination of Core Parameters

• Range Selection: Select a model with a range 1.3 - 1.6 times the actual maximum load (e.g., for a maximum load of 10t, a 13 - 16t sensor can be selected), leaving sufficient overload margin to avoid damage from impact loads.

• Accuracy Class: For industrial metrology, select Class C3 (error ≤ ±0.02%FS); for scientific research testing, select Class C2 (error ≤ ±0.01%FS); for general monitoring, select Class C6 (error ≤ ±0.03%FS).

• Signal Type: For traditional control systems, select analog signals (4 - 20mA); for intelligent IoT systems, select digital signals (RS485); for construction machinery, select models with the CANopen protocol.

2) Selection Based on Environmental Adaptability

• Temperature: For normal scenarios (-30°C ~ 60°C), select ordinary models; for high-temperature scenarios (60°C ~ 120°C), select high-temperature compensation models; for low-temperature scenarios (-50°C ~ -30°C), select low-temperature-resistant models.

• Medium: For dry environments, select alloy steel; for humid/slightly corrosive environments, select 304 stainless steel; for highly corrosive environments (acid-base solutions), select 316L stainless steel or Hastelloy materials.

• Protection Class: For indoor dry environments, ≥IP66; for outdoor/humid environments, ≥IP67; for underwater or dust-intensive environments, ≥IP68.

3) Installation and System Compatibility

• Installation Method: For narrow spaces, select end-face bolt connections; for large-load scenarios, select flange connections; if there is obvious eccentric load, prefer enhanced models with an eccentric load error ≤ ±0.01%FS.

• Compatibility: Confirm that the sensor signal matches the Communication Protocol of the existing instrument/PLC. When multiple sensors are used in combination, select digital models that support address coding to avoid signal conflicts. 4) Confirmation of Additional Requirements

• Certification Requirements: Explosion-proof scenarios require corresponding explosion-proof grade certification (e.g., Ex d I for coal mines, Ex ia IIC T6 for chemical industries), the food industry requires FDA/GMP certification, and metrology scenarios require CMC certification.

• Special Functions: For dynamic weighing, select models with a response time ≤ 5ms; for remote monitoring, select intelligent models with LoRa/NB-IoT wireless modules; for high-temperature scenarios, select special models with temperature compensation chips.

Summary

The spoke-type weighing sensor has the core advantages of "strong anti-bias load, compact structure, and high stability", which solves the problem of accurate weighing under medium and low loads, limited space, and biased load conditions. User Experience focuses on convenient installation, worry-free maintenance, and reliable data. When selecting, the four core requirements of range, accuracy, installation space, and environment should be given priority, and system compatibility and additional function decisions should be combined. During use, the principle of axial force installation and regular calibration specifications should be strictly followed to ensure long-term stable operation. It is suitable for industrial scales, engineering machinery, process control and other fields, and is an ideal weighing sensing solution for medium and low loads and special installation scenarios.

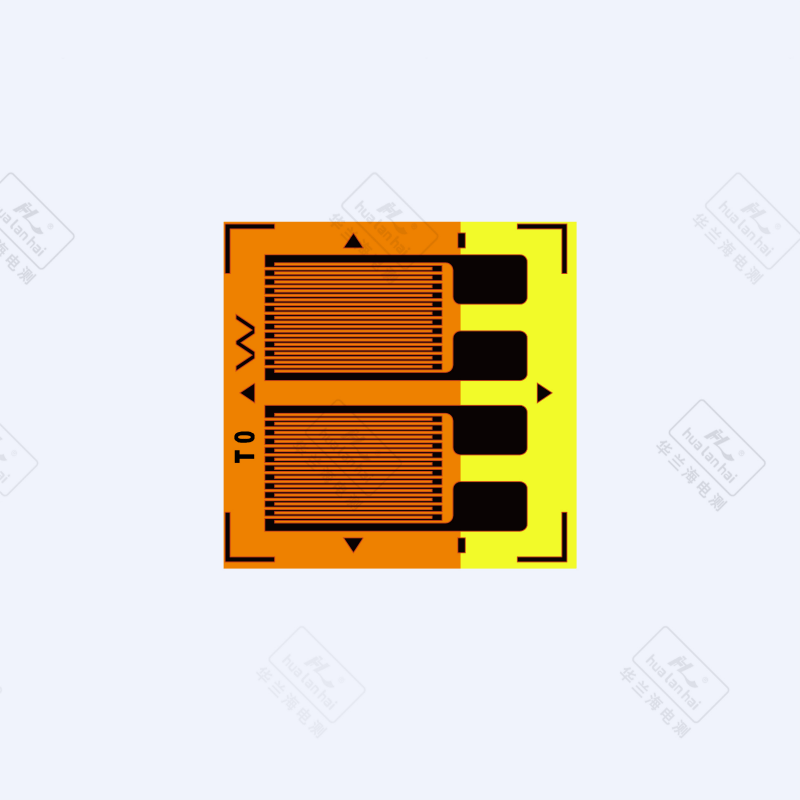

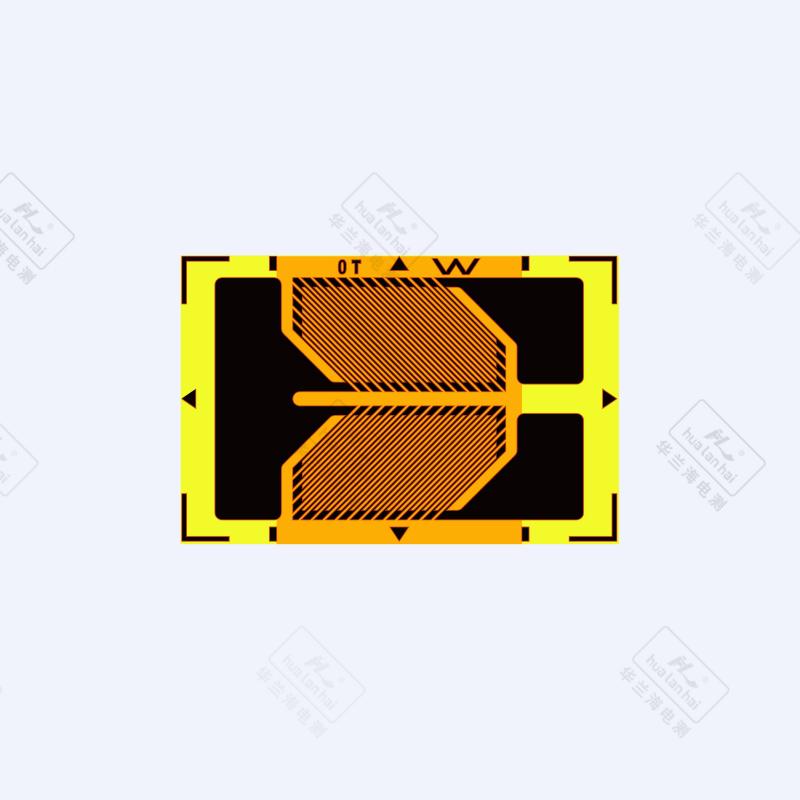

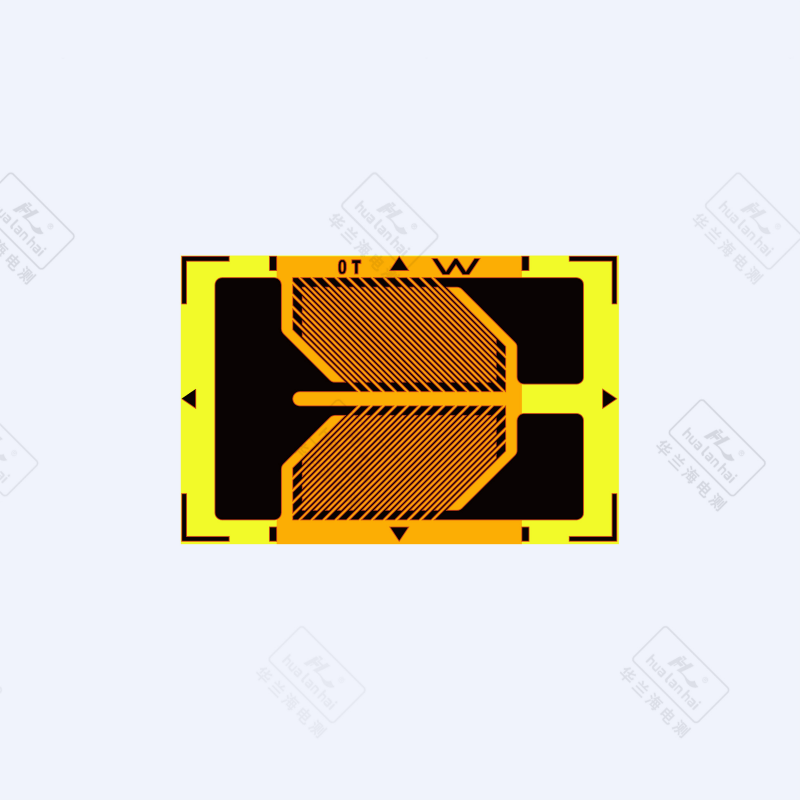

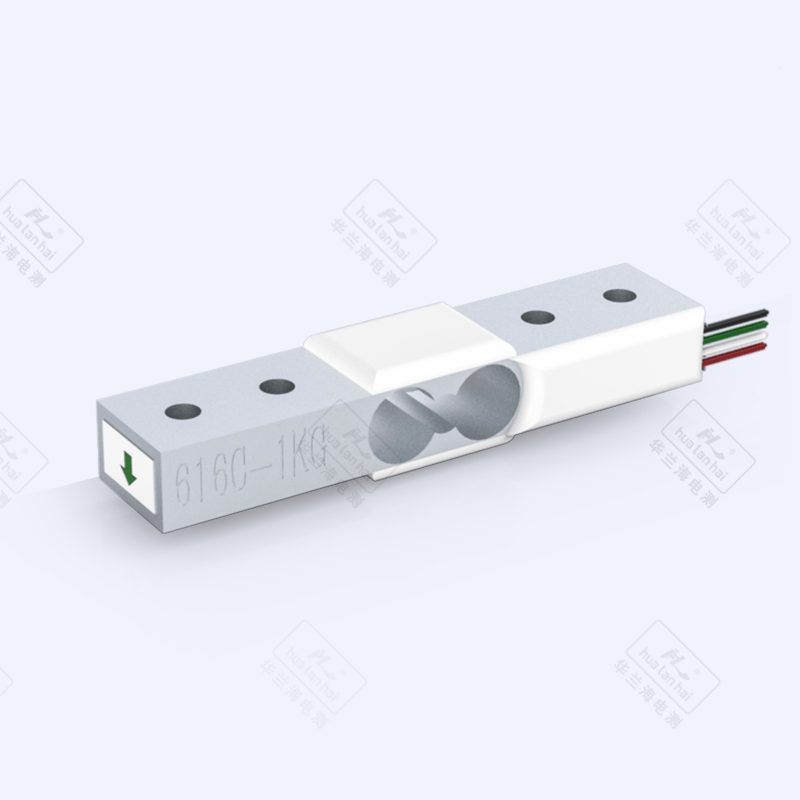

Detail Display

Parameters

| Parameter Name | Parameter Value |

| Sensor range | 1t ~ 50t |

| Accuracy class | C1/C2 |

| Comprehensive error | ±0.05 & ±0.03% FS |

| Output sensitivity | 2.0±0.01 mV/V |

| creep | ±0.038 & ±0.023% FS/30min |

| Zero output | ±1.5% FS |

| Input impedance | 700±10Ω |

| Output impedance | 700±5Ω |

| insulation resistance | ≥5000 MΩ(100VDC) |

| Influence of zero temperature | ±0.047 & ±0.029% FS/10℃ |

| Sensitivity temperature effect | ±0.028 & ±0.017% FS/10℃ |

| Temperature compensation range | -10℃ ~ +40 ℃ |

| Operating temperature range | -30℃ ~ +70 ℃ |

| Excitation voltage | 5VDC ~ 12VDC |

| Safe overload range | 150% |

| Limit overload range | 200% |

| Material Science | Alloy Steel or Stainless Steel |

| Protection level | IP66 |