- Oorsig

- Aanbevole Produkte

Produk Inleiding

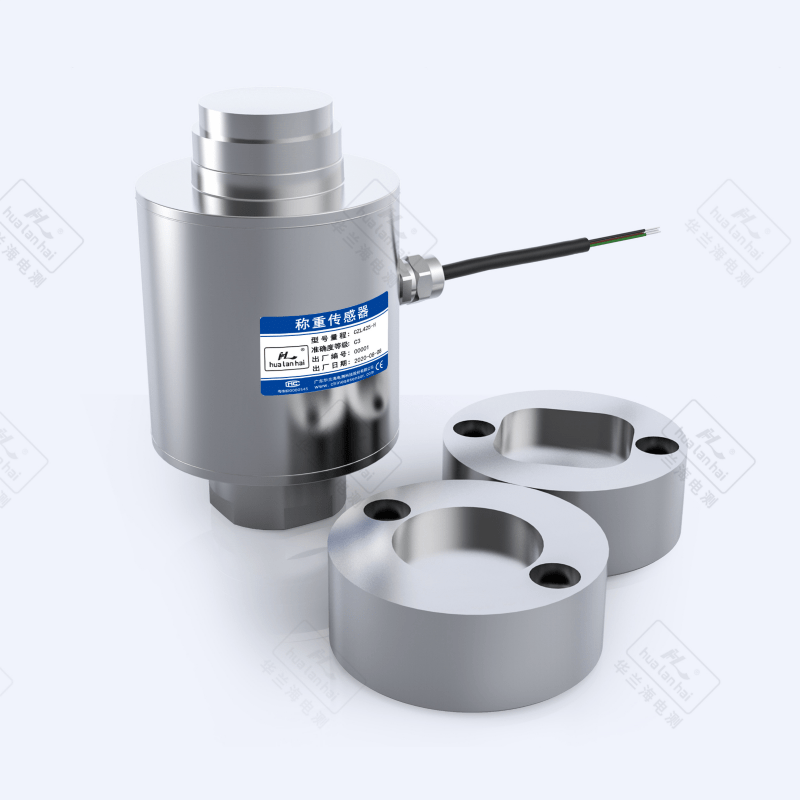

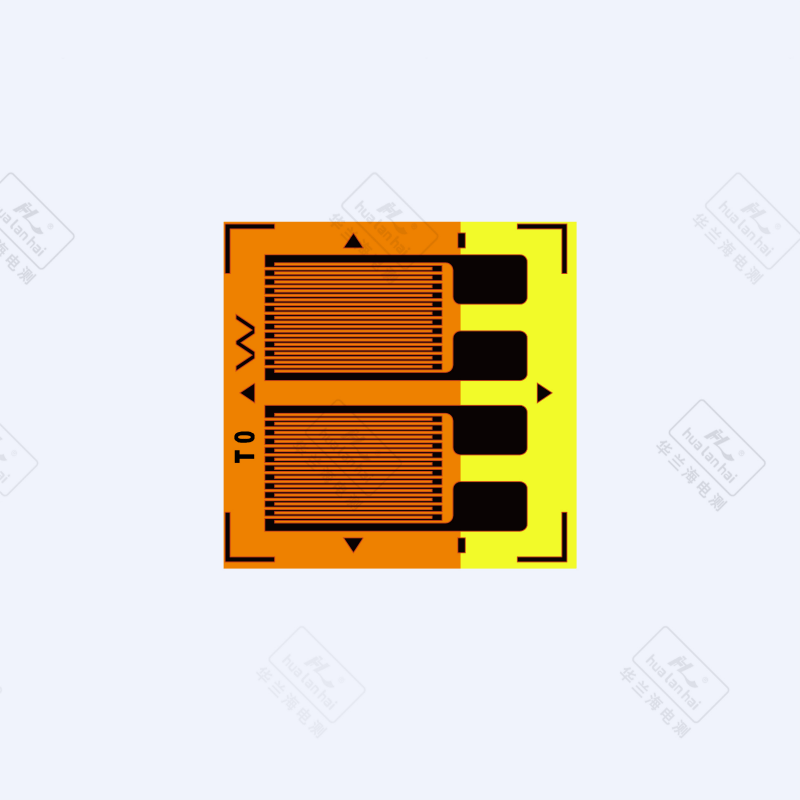

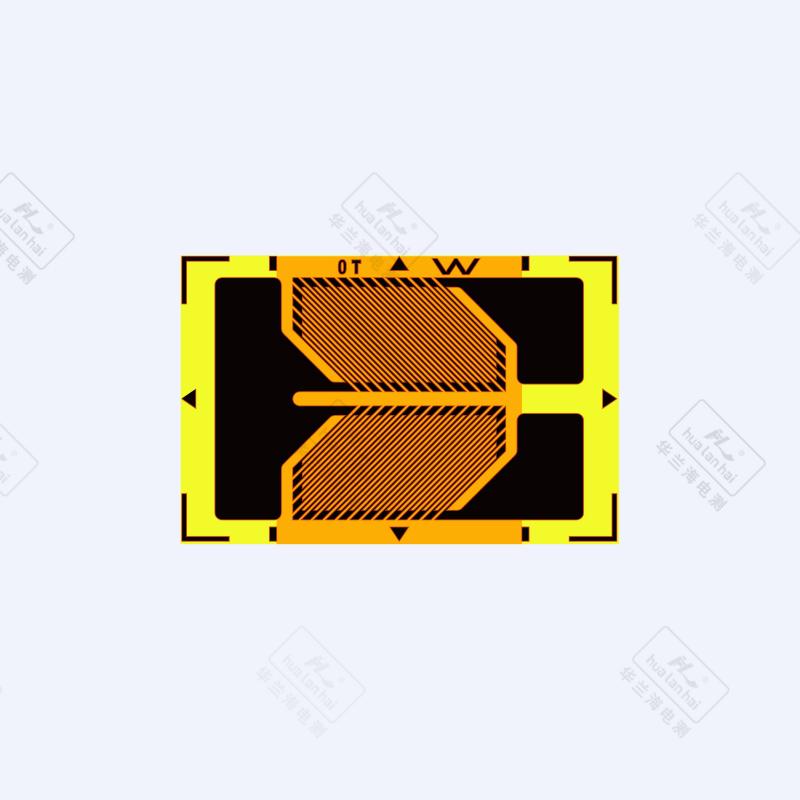

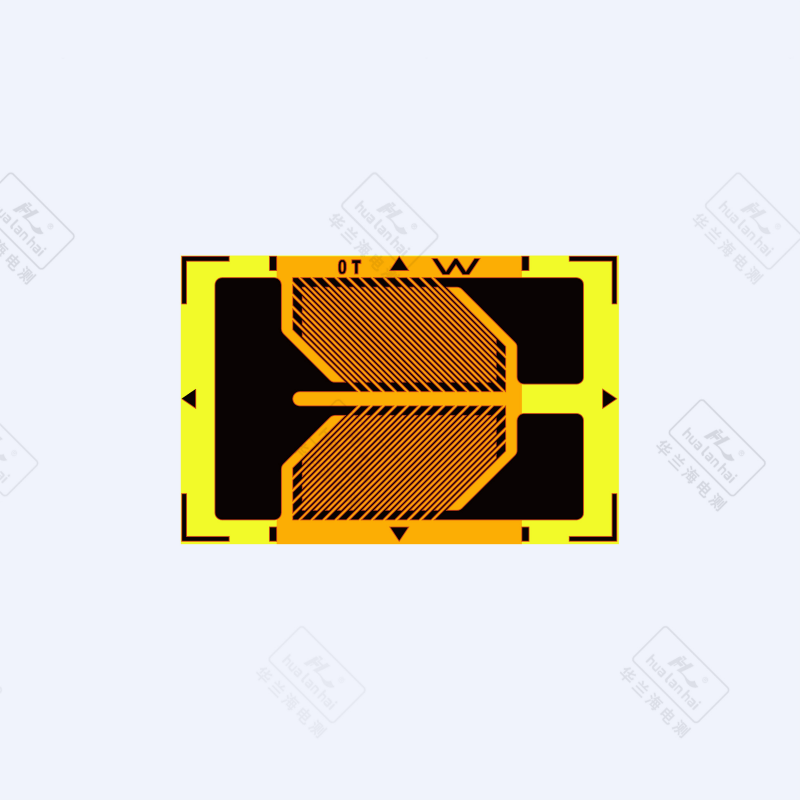

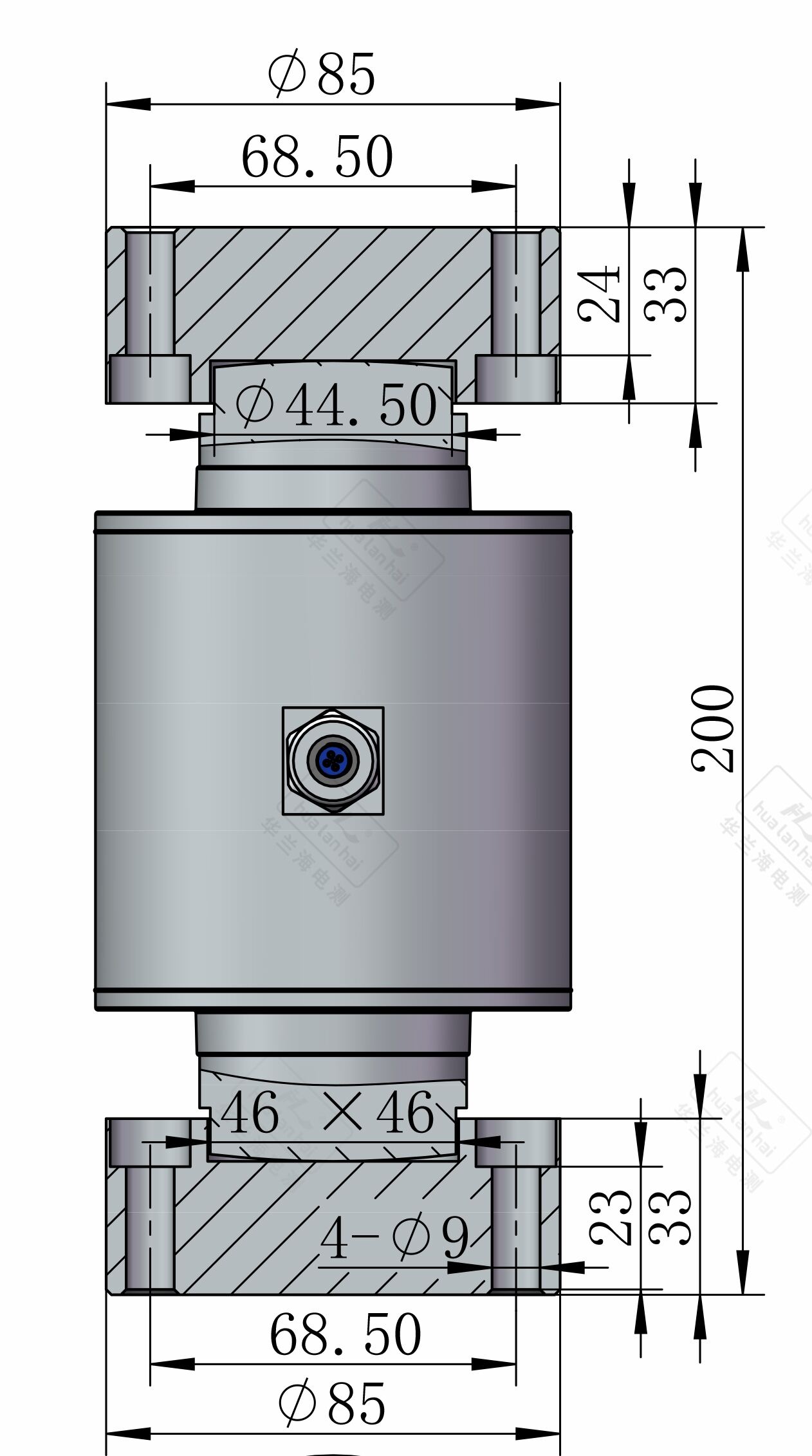

Kolom weegselle is kraggevoelige komponente gebaseer op die rekstrookbeginsel. Hulle genereer rek deur die vervorming van 'n silindriese elastiese liggaam onder krag, wat dan omgeskakel word na 'n elektriese sein deur die rekstrook. Hulle het hoë styfheid, sterk anti-ontsteurvermoë, ens., en word wyd gebruik in medium- en swaarlas weegtoepassings. Die volgende besonderhede word aangebied vanaf die kerndimensies om te voldoen aan die behoeftes van produk keuse, tegniese evaluering en oplossingskommunikasie:

1. Produkkenmerke en Funksies

Kernkenmerke

• Strukturele ontwerp: Sillindriese elastomeer (deursnee 10-100 mm opsioneel), hoë-styfheidsontwerp (hoë natuurlike frekwensie), sterk weerstand teen sentrumafwykende las/laterale krag (gewoonlik in staat om laterale kragte van ±5% tot ±10% van die genommerde las te hanteer), en goeie kraguniformiteit.

• Presisie prestasie: Hoë presisiegraad (algemeen C3, C6, met sommige hoogwaardige modelle wat C1 bereik), nie-liniêre fout ≤±0,01%VS, herhaalbaarheidfout ≤±0,005%VS, en klein nuldrif (≤±0,002%VS/℃).

• Materiale en Beskerming: Elastomeermateriaalkans sluit in legeringsstaal (ekonomiese weergawe, vloeisterkte ≥800 MPa) of roestvrye staal (304/316L, korrosiebestand), met beskermingsgraad IP67/IP68 opsioneel, geskik vir vogtige, stowwerige en effens korrosiewe omgewings.

• Installasiekompatibiliteit: Beide ente is berader (M12-M60) of flensverbinding, met 'n kompakte installasieruimte, geskik vir vertikale/aksiale kragtoepassings, en veelvuldige sensore kan parallel verbind word om 'n skaal te vorm (ondersteun 4-8 sensore wat gelyktydig werk).

Kernfunksies

• Krag/Gewigmeting: Ondersteun statiese/dinamiese weging (dinamiese reaksie tyd ≤ 5 ms), met 'n wye meetreeks (1 t - 500 t, sommige aangepaste modelle kan 1000 t bereik).

• Signaal uitvoer: Verskaf analoog seine (4 - 20 mA, 0 - 10 V) of digitale seine (RS485/Modbus, HART), wat versoenbaar is met hoofstroom weeginstrumente, PLC's en DCS-stelsels.

• Aanvullende funksies: Sommige modelle integreer temperatuurkompensasie (-20°C - 80°C kompensasieweë), oorbeladingbeskerming (150% - 200% van genommerde las), ontploffingsbestendige sertifisering (Ex ia IIC T6) en bliksembeveiligingsontwerp.

• Langtermyn betroubaarheid: Lang vermoeë lewensduur (≥ 10⁶ las siklusse), goeie nulpuntstabiliteit, en jaarlikse drywing ≤ ±0,01%VS.

2. Kernprobleme opgelos

•Onvoldoende meetakkuraatheid: Om die probleme van swak weerstand teen eksentriese las en groot datafluktuasies in tradisionele sensore aan te pak, word 'n hoë-styfheidsstruktuur en presiese spanningmeter-kleeftegnologie gebruik om te verseker dat die meetfout ≤ ±0,02%VS onder eksentriese lasomstandighede bly.

•Swak aanpasbaarheid aan harde omgewings: Rooivrye staalmateriaal + IP68-beskermingsontwerp los die probleme van sensorskade en seinverskuiwing op in toestande met vogtigheid, stof, suur-basis korrosie (soos chemiese silo's en buite weeginstrumente).

•Installasie- en ruimtebeperkings: Kompakte silindriese struktuur + fleksibele verbindingsmetode los die probleme van beperkte installasieruimte en moeilike aksiale kragstuur in groot toerusting op (soos reaksieketels en hydrolieë).

•Stabiliteit van swaarlasmeting: Hoë-rigiditeit elastomeer + oorbeladingsbeskermingsontwerp voorkom permanente vervorming van sensore in medium- en swaarlas-toepassings (soos vragmotorskale en hawecontainerweegstelsels), wat langtermynmetingsbetroubaarheid verseker.

•Stelselverenigbaarheidsprobleme: Verskeie seinuitvoermodusse is beskikbaar om koppelingprobleme met verskillende beheerstelsels op te los (soos Siemens PLC en Kunlun Tongtai touch screen), wat die nodigheid van addisionele seinomsetters elimineer.

3. Gebruikerservaring

•Installasie gerief: Gestandaardiseerde skroef-/vleisioenpasstukke, saam met installasiesleutels en liggingpenne, maak dit moontlik vir een persoon om dit te installeer; horisontale verstelgate word onderaan gereserveer vir maklike kalibrasie van die kragrigting.

• Bediening en Kalibrasie: Nulkalibrasie is eenvoudig (een-knoppie-nul via die meter), ondersteun kalibrasie met standaardgewigte (kalibrasieproses ≤ 10 minute), en sommige digitale modelle kan op afstand gekalibreer word via sagteware.

• Lae onderhoudskoste: Geseëlde strukturele ontwerp elimineer die behoefte aan gereelde onderhoud; spanningsmeters is bedek met vogbestand materiaal, wat lei tot lae foutkoerse (jaarlikse gemiddelde foutkoers ≤ 0,5%); dele wat maklik vervang kan word (soos terminalblokke) kan individueel vervang word.

• Data Terugvoer: Vinnige seinrespons, geen datalag in dinamiese weegtoestande nie; digitale modelle word verskaf met ingeboude foutdiagnosefunksies (soos oorlasalarm, bedradingonreëlmatigheidsprompt) vir vinnige foutopsporing.

• Verenigbaarheidsondervinding: Vereenselwig met meer as 90% van die weeginstrumente en beheerstelsels op die mark, geen behoefte om hardewarekoppelvlakke te wysig nie, Plug and Play; ondersteun parallelle aansluiting van verskeie sensore met outomatiese lasverdeling.

4. Tipiese Gebruiksscenario's

1) Industriële Weeg- en Metingstoepassings

• Silo/Tankweeg: Gewigmonitoring van poeier/vloeistofsilos in die chemiese en boumateriale-industrieë, ondersteun vlakbeheer en voorraadbestuur (gewoonlik met 4 sensore simmetries geïnstalleer).

• Vragmotorweegskaal/Spoorwegskaal: Weeg van pad- en spoorweggoed, met 'n enkele sensorvermoë van 50-200 t, veelvuldige sensore wat parallel verbind word om 'n weegplatform te vorm (byvoorbeeld gebruik 'n 100 t vragmotorweegskaal gewoonlik 4 25 t sensore).

• Reaktorweeg: Regstydse gewigmonitoring van reaktore in die farmaseutiese en chemiese industrieë, werk saam met die beheerstelsel om presiese voerbekontrole te bewerkstellig (ontploffingsvaste sensore vereis).

2) Integrasie van Materiaal en Toerusting

• Kranse/Oorhoofse Kranse Oorlaai Beskerming: Monitorering van die hefvermoë van krane in hawens en fabrieke, wat 'n alarm aktiveer wanneer die las die geassessmenteerde waarde oorskry (modelle met vibrasiebestandheid en vinnige reaksie word vereis).

• Pers/Toetsmasjien: Meting van druk/trekkrag in materiaalmeganika-toetsing, wat hoë presisie (C1-vlak) en hoë dinamiese reaksie (≤3ms) vereis.

• Boumasjinerie: Weeg van saamgestelde mengsels in betonmengaanleggings en oorlaaibeskerming van toringkrane, geskik vir buite natte en vibrerende omgewings (beskermingsvlak ≥IP67).

3) Vervaardiging van Weeginstrumente

• Kernkomponente van Tafelweë/Vloerweë: Kern sensoreenhede van klein- en mediumgrootte tafelweë (1-5t) en groot vloerweë (50-500t), wat goeie konsekwentheid vereis (fout van veelvuldige sensore ≤±0,01%VS).

• Aangepaste Weeginstrumente: Soos ontploffingsbestande elektroniese weegskaale en korrosiebestande industriële weegskaale, wat roestvrye staalmateriaal en ontploffingsbestande gesertifiseerde sensors gebruik, geskik vir die behoeftes van spesiale nywerhede.

4) Ander Spesiale Skenarios

• Voedsel/Farmaseutiese Nywerheid: Higiëniese roestvrye staalsensors (316L materiaal, oppervlak gepoleer), gebruik vir grondstofweëning en dosering van klaargemaakte produkte, in ooreenstemming met GMP-standaarde.

• Mynbou/Metallurgie Nywerheid: Aangepaste modelle vir hoë-temperatuur omgewings (≤120℃), gebruik vir erts-hopper weging en gewigmonitoring van metallurgiese oonde (vereis hoë-temperatuur kompensasie-funksie).

5. Gebruiksinstruksies (Praktiese gids)

1) Installasieproses

• Voorbereiding: Maak die installasieoppervlak skoon (moet vlak wees, olievry, met vlakheidfout ≤0,1 mm/m), en inspekteer die voeler se voorkoms (geen vervorming, ongeskonde terminaalblokke). • Posisionering en Vasstelling: Installeer die voeler vertikaal by die laspunt om te verseker dat die las aksiaal oorgedra word (vermy laterale kragte); gebruik 'n moment sleutel om dit volgens die gespesifiseerde moment vas te draai (20-50 N·m aanbeveel vir legeringsstaal voelers, 15-30 N·m vir roestvrye staal).

• Bedrading Spesifikasies: Vir analoog seine (rooi - krag +, swart - krag -, groen - sein +, wit - sein -), en vir digitale seine, bedraad volgens die Modbus protokol; hou tydens bedrading weg van hoë-spanningslyne (≥10 cm) om elektromagnetiese interferensie te vermy.

• Beskerming Behandeling: Vir buite-installasie, voeg 'n reëndeksel by, en verseël die bedradingaansluitings met waterdigte konnektors; in korrosiewe omgewings, bring 'n anti-korrosie deklaag aan op die voeleroppervlak.

2) Kalibrasie en Ontsteuring

• Nulkalibrasie: Skakel die krag aan en verhit voor vir 30 minute, druk dan die „nul“-knoppie op die meter om seker te maak dat die nul-uitset binne ±0,001%VS is.

• Laskalibrasie: Plaas standaardgewigte (aanbeveel om 50% en 100% van die nomina-lading te wees), neem die meterlesings op en korrigeer die fout deur middel van die meter of sagteware (die fout moet ≤ die toelaatbare fout wat ooreenstem met die akkuraatheidsklas wees).

• Dinamiese foutsoek: In dinamiese weegtoestande, toets die sensor se reaksie-tyd, stel die meter se filterparameters aan (gewoonlik is die filterfrekwensie 5-10 Hz) om datafluktuasies te vermy.

3) Gewone instandhouding

• Reëlmatige inspeksie: Maak die sensors oppervlak maandeliks skoon, kontroleer of die bedrading los is; kalibreer die nulpunt een keer per kwartaal, en voer 'n volledige kalibrasie een keer per jaar uit.

• Foutafhandeling: As datadryf voorkom, kontroleer die toevoerspanning (moet stabiel wees by 12-24 V DC); as daar geen seinuitset is nie, kontroleer of die bedrading korrek is of of die sensor oorbelas en beskadig is.

6. Kiesmetode (Presies pas vereistes aan)

1) Bepaling van Kernparameters

• Omvangkeuse: Kies 'n model met 'n omvang van 1,2 - 1,5 keer die werklike maksimum las (byvoorbeeld vir 'n maksimumlas van 50 t kan 'n 60 - 75 t-sensor gekies word), met 'n marge vir oorlas.

• Akkuraatheidsklas: Vir industriële metrologie, kies Klas C3 (fout ≤ ±0,02%VS); vir laboratoriumtoetsing, kies Klas C1 (fout ≤ ±0,01%VS); vir algemene monitering, kies Klas C6 (fout ≤ ±0,03%VS).

• Seintipe: Analoge seine (4 - 20 mA) is geskik vir tradisionele instrumente, terwyl digitale seine (RS485) geskik is vir intelligente beheerstelsels en afstandsbewaking ondersteun.

2) Keuse op grond van Omgewingsaanpassing

• Temperatuur: Vir normale toestande (-20°C - 60°C), kies 'n standaardmodel; vir hoë-temperatuur toestande (60°C - 120°C), kies 'n hoë-temperatuur gekompenseerde model; vir lae-temperatuur toestande (-40°C - -20°C), kies 'n lae-temperatuur bestandige model.

• Medium: Vir droë omgewings, kies gelegeer staal; vir vogtige/korrosiewe omgewings, kies 304/316L roestvrye staal; vir hoogs korrosiewe omgewings (bv. suur-basis oplossings), kies Hastelloy.

• Beskermingsklas: Vir buite/vogtige omgewings, ≥ IP67; vir onderwater- of stowwerige omgewings, ≥ IP68.

3) Installasie en Stelselverenigbaarheid

• Installasie Metode: Vir beperkte ruimte, kies draadverbindinge; vir groot lasse, kies flensverbindinge; indien daar 'n risiko van eksentriese las is, kies 'n model met anti-eksentriese las ontwerp (eksentriese las fout ≤ ±0,01%FS).

• Verenigbaarheid: Bevestig dat die sensor se uitgangsseinskool ooreenstem met die bestaande instrumente/PLC's; indien veelvuldige sensore parallel aangesluit moet word, kies 'n digitale model wat adresinstelling ondersteun.

4) Bevestiging van Aanvullende Vereistes

• Sertifiseringsvereistes: Ontploffingsbestande toepassings vereis Ex ia IIC T6-sertifikasie; die voedselbedryf vereis FDA/GMP-sertifikasie; metrologietoepassings vereis CMC (Metrologiese Instrumenttipe-goedkeuringsertifikaat).

• Spesiale Funksies: Vir dinamiese weging, kies 'n model met 'n reaksietyd ≤ 5 ms; vir afstandsbewaking, kies 'n intelligente model met draadlose oordrag (LoRa/NB-IoT).

Samevatting

Kolomtrekkragopnemers word gekenmerk deur "hoë styfheid, anti-afskerming en wye variasie" as hul kernvoordele, wat hoofsaaklik probleme soos presiese weging, aanpassing aan harde omgewings en stelselverenigbaarheid in medium tot swaar las-toepassings aanspreek. Gebruikerservaring fokus op maklike installasie, eenvoudige instandhouding en stabiele data. Wanneer 'n trekkragopnemer gekies word, is dit nodig om eers die drie kernevereistes van meetbereik, akkuraatheid en omgewing te verduidelik, en dan 'n besluit te neem in kombinasie met die installasiemetode en stelselverenigbaarheid; tydens gebruik moet daar streng aan die beginsels van as-kraginstallasie en gereelde kalibrasie voldoen word om langtermynbetroubaarheid te verseker. Hulle is geskik vir velde soos industriële metrologie, meganiese integrasie en wegingsinstrumentvervaardiging, en is die verkose sensortipe vir medium tot swaar las-wegingstoepassings.

Detailweergawe

Parameters

| Parameter Naam | Parameterwaarde |

| Gegradeerde las | 10t/20t/30t/40t |

| Naukeurigheid | C2/C3 |

| Samestellingsfout | ±0.03 & ±0.02% VS |

| GERENOMIEERDE produksie | 2.0±0.01 mV/V |

| Sukkel | ±0.023 & ±0.016% VS/30min |

| Nulbalans | ±1.5% VS |

| Invoerweerstand | 700±10Ω |

| Uitgangsweerstand | 700±5Ω |

| Isolasie weerstand | ≥5000 MΩ(100VDC) |

| Temperatuur-effek op omvang | ±0,017 & ±0,011% VS/10℃ |

| Temp. effek op nul | ±0,029 & ±0,019% VS/10℃ |

| Gekompenseerde temp.reeks | -10℃ ~ +40 ℃ |

| Gebruik temp.reeks | -30℃ ~ +70 ℃ |

| Uitlokvoltage | 10VDC ~ 12VDC |

| Veilige oorbelasting | 150% |

| Uiteindelike oorlading | 200% |

| IP-kode | IP68 |