- Overview

- Recommended Products

- Wide Pressure Range Adaptability: Covers multiple measurement types (absolute pressure, gauge pressure, differential pressure) with ranges from micro-pressure (0–1kPa) to high pressure (0–100MPa or higher). Suitable for diverse scenarios, such as low-pressure monitoring in medical devices and high-pressure measurement in industrial hydraulic systems.

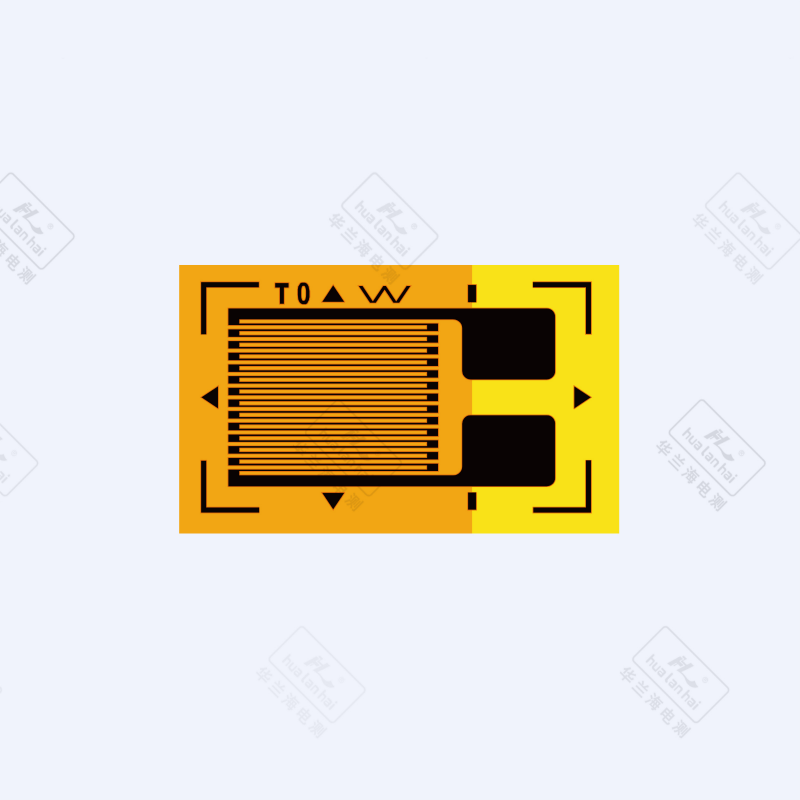

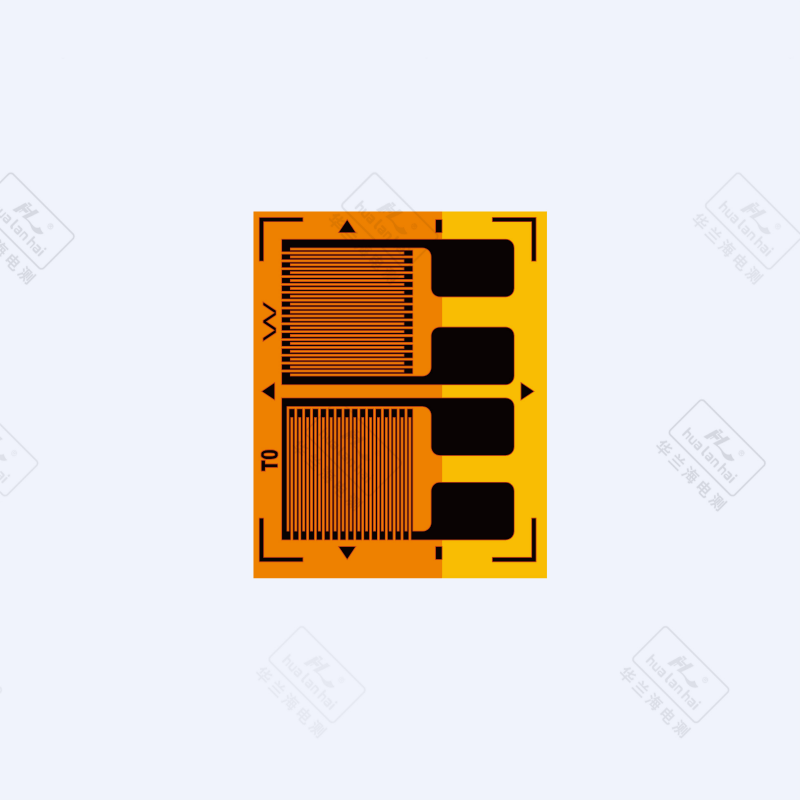

- High Precision and Linearity: Using precision strain gauges and optimized bonding processes, measurement accuracy reaches ±0.05%FS–±0.25%FS, with linearity ≤±0.1%FS. Capable of capturing subtle pressure fluctuations to meet precision production and metrology needs.

- Good Medium Compatibility: Elastic sensing elements are made of materials like 316L stainless steel, titanium alloy, or Hastelloy, combined with sealed structural designs. Compatible with water, oil, acid/alkaline solutions, high-temperature steam, and other media, preventing corrosion damage.

- Multi-Type Signal Output: Sensors typically output resistance signals, while transmitters support analog signals (4-20mA, 0-10V, 0-5V) and digital signals (RS485-Modbus, HART). Directly connectable to PLCs, DCS systems, data loggers, etc., for real-time data transmission.

- Full-Condition Compensation Function: Built-in temperature compensation modules effectively offset the impact of ambient temperatures (-40°C–120°C; special models up to 200°C) on measurement accuracy. Some models feature automatic zero drift compensation and non-linear compensation for enhanced long-term stability.

- Anti-Interference and Protection Capability: Adopts electromagnetic shielding to resist electromagnetic radiation and grid fluctuations in industrial environments. Protection ratings reach IP65–IP68, with dustproof and waterproof performance, suitable for harsh conditions (moisture, dust, vibration) like mines and outdoor pipe networks.

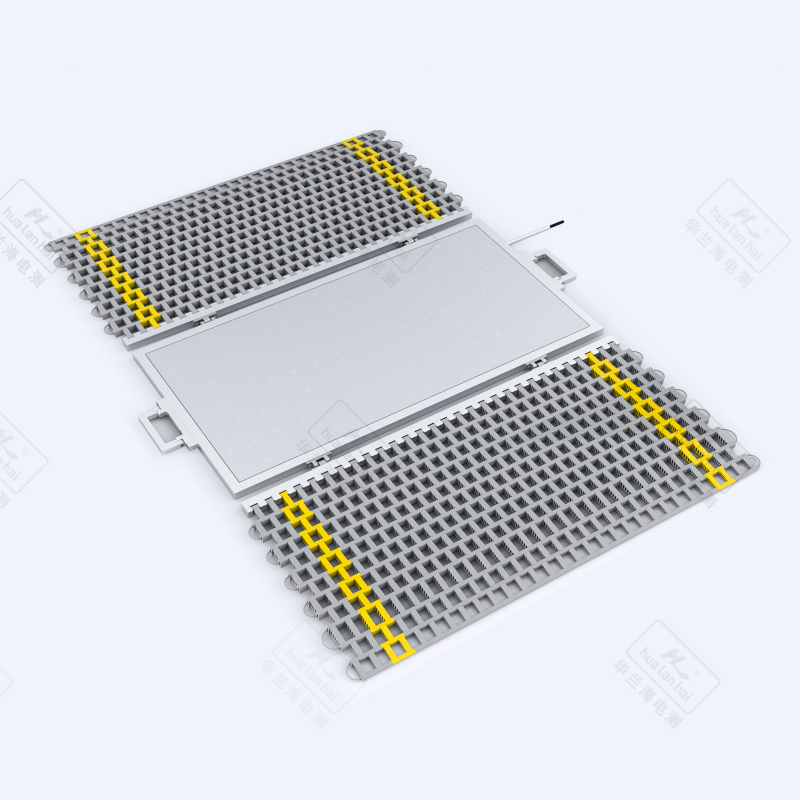

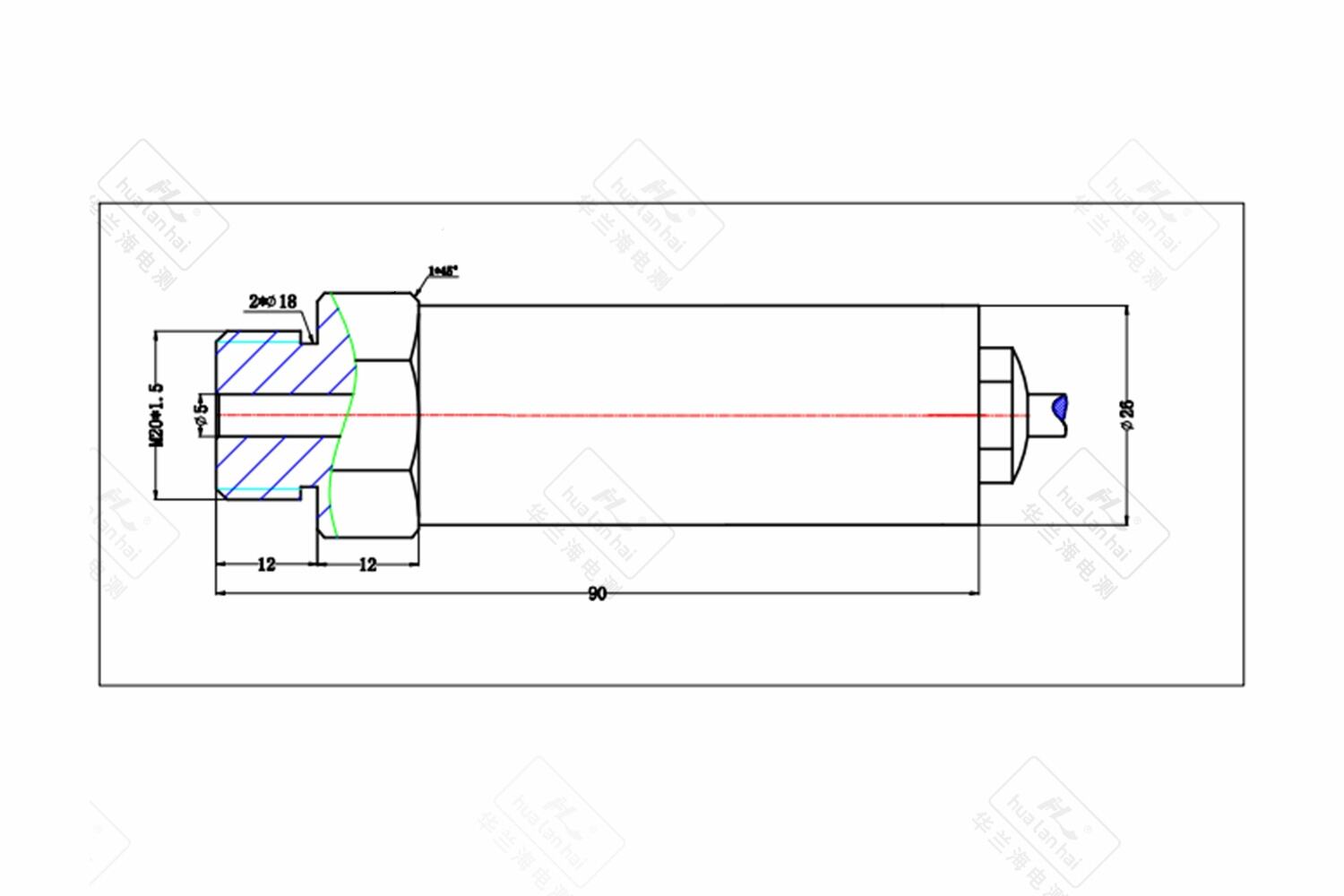

- Flexible Installation Design: Supports multiple installation methods (threads: M20×1.5, G1/2; flanges; clamps). Customizable installation structures based on pipeline/equipment dimensions, requiring no large-scale modifications.

- Overload and Explosion-Proof Protection: Withstands 150%–300%FS overload to prevent damage from sudden pressure changes. Explosion-proof models comply with standards like Ex d II CT6, suitable for flammable/explosive scenarios (petroleum, chemical industries).

- Additional Smart Functions: High-end models include LCD display heads for on-site pressure reading; support remote calibration and self-diagnosis. Some allow parameter configuration and data monitoring via mobile apps or cloud platforms.

- Complex Working Condition Adaptation: Solves the problem of traditional instruments being prone to damage and short lifespans under high-temperature, high-pressure, or strongly corrosive media (e.g., high-temperature pressure monitoring in chemical reactors), preventing production interruptions due to equipment failure.

- Inadequate Pressure Measurement Precision: Addresses large reading errors and slow dynamic response of mechanical instruments (e.g., pressure control in precision hydraulic systems), ensuring pressure stability within process requirements and improving product pass rates.

- Automation Integration Barriers: Resolves signal incompatibility of traditional sensors with modern measurement and control systems. Transmitters’ standardized signals integrate directly into industrial automation networks, supporting digital upgrades of production processes.

- Environmental Interference Impact: Mitigates measurement data distortion caused by temperature drift or electromagnetic interference (e.g., high-temperature pressure monitoring in metallurgical workshops), ensuring stable and reliable data in complex environments.

- High Operation and Maintenance Costs: Reduces frequent calibration and replacement of traditional instruments. Their long lifespan (MTBF ≥80,000 hours) and low-maintenance design lower equipment replacement and labor costs.

- Convenient Installation and Debugging: Standardized interfaces and universal installation methods enable completion in 15–30 minutes. Simple zero and range calibration during debugging requires no specialized skills, lowering technical thresholds.

- Intuitive Data Acquisition: Models with displays allow real-time on-site reading without relying on control systems. Digital signal models support remote data transmission, facilitating monitoring by managers in control rooms or via mobile devices.

- Worry-Free Long-Term Use: Excellent stability limits annual drift to ≤±0.1%FS, eliminating frequent calibration. Self-diagnosis functions provide timely feedback on equipment status (e.g., overload, circuit faults), simplifying pre-emptive maintenance.

- Reasonable Cost Control: Mature production processes reduce procurement costs, offering better cost-effectiveness than piezoelectric or capacitive pressure devices. Long lifespan and low maintenance further lower lifecycle costs.

- Strong System Compatibility: Seamlessly connects with PLCs and DCS systems from mainstream brands (Siemens, Mitsubishi, Rockwell) without additional signal converters, reducing integration costs.

- Hydraulic and Pneumatic Systems: Monitor hydraulic pump outlet pressure and cylinder operating pressure (e.g., pressure control in injection molding machine hydraulic systems) to ensure stable molding and prevent defects (flash, shortages).

- Chemical Production: Used for pressure monitoring and control in reactors and distillation columns (e.g., high-pressure monitoring in ammonia synthesis reactors). Linked to safety valves for overpressure protection, ensuring production safety.

- Oil and Gas: Monitor pressure at oil wellheads and pipelines (e.g., crude oil pipeline pressure monitoring) to detect leaks or blockages, safeguarding transportation safety.

- Power Generation: Monitor boiler steam pressure and turbine oil pressure (e.g., high-temperature steam pressure control in thermal power plant boilers) to ensure stable operation of power equipment.

- Water Supply Systems: Monitor pressure in water supply pipelines and secondary water supply equipment (e.g., pressure control in community secondary water supply) to prevent pipe bursts (high pressure) or insufficient water supply (low pressure).

- Wastewater Treatment: Monitor pressure in sewage pumps and reaction tanks (e.g., pressure monitoring at sewage lift pump outlets) to ensure smooth sewage transport and avoid equipment overload.

- Medical Equipment: Used for airway pressure monitoring in ventilators and pressure control in infusion pumps (e.g., pressure monitoring in ICU ventilators) to ensure airflow meets patient needs and treatment safety.

- Food Processing: Monitor pressure and temperature in food sterilization kettles (e.g., pressure control during can sterilization) to ensure sterilization effectiveness while preventing packaging damage.

- Aviation Equipment: Monitor aircraft hydraulic system pressure and fuel pipeline pressure (e.g., hydraulic actuator pressure monitoring in fighter jets) to ensure stable control during flight.

- Military Testing: Used for pressure measurement in weaponry tests (e.g., bore pressure testing during artillery firing) to provide precise data for equipment performance optimization.

Product Introduction

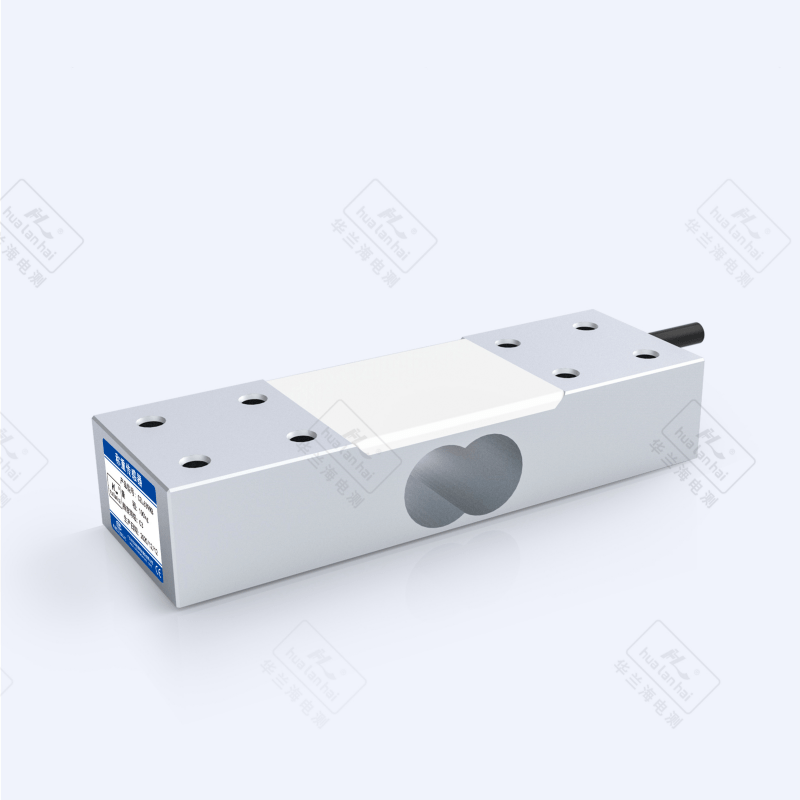

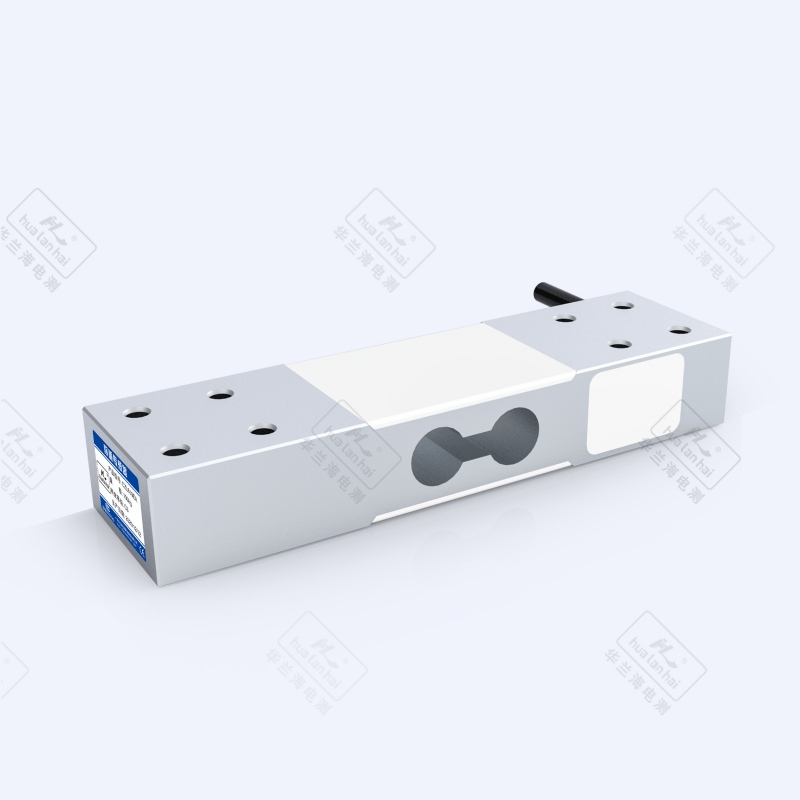

Strain gauge pressure sensors/transmitters are pressure measurement devices developed based on the "strain effect." Their core mechanism involves strain gauges bonded to elastic sensing elements, which convert mechanical deformation under pressure into resistance changes. These changes are then transformed into standard electrical signals via signal conditioning circuits. Sensors focus on pressure signal detection, while transmitters integrate signal amplification, compensation, and conversion functions, enabling direct connection to measurement and control systems. Widely used in petrochemical, hydropower, industrial control, aerospace, and other fields, they are core devices for pressure monitoring in industrial automation.

1. Core Features And Functions

1) Core Characteristics of Pressure Measurement

2) Key Functional Performance

3) Structural And Usage Characteristics

2. Core Industry Pain Points Addressed

In pressure measurement scenarios, traditional pressure instruments (e.g., mechanical pressure gauges, basic sensors) often suffer from "inaccurate measurement, poor adaptability, difficult integration, and frequent maintenance." Strain gauge pressure sensors/transmitters specifically resolve these issues:

3. User Experience Highlights

4. Typical Application Scenarios

1) Industrial Control Field

2) Energy And Power Field

3) Water Conservancy And Municipal Fields

4) Medical And Daily Life Fields

5) Aerospace And Military Fields

Smmary

Strain gauge pressure sensors/transmitters, with core competitiveness in "precision, reliability, strong adaptability, and high cost-effectiveness," have become indispensable devices in industrial automation and people’s livelihood fields by addressing pressure measurement pain points across diverse scenarios. Their capabilities—from basic pressure sensing to intelligent signal transmission and remote monitoring—not only ensure production safety and product quality but also drive digital and intelligent upgrades across industries, providing robust support for efficient production and convenient daily life.(来自飞书知识问答|https://ask.feishu.cn)

Detail Display

Parameters

| Parameter Name | Parameter Value |

| Pressure Range | 0-6MPa ~ 0-150MPa |

| Accuracy | 0.2% FS;0.3% FS;0.5% FS;1.0% FS |

| Output Signal | 4mA ~ 20mA;0V ~ 5V;0V ~ 10V |

| Excitation Voltage | 24VDC |

| Thread Connection | M20*1.5;Customize |

| Use Temp Range | -10℃ ~ 80℃ |

| Burden Resistance | Electric Current output:≤800Ω;Voltage output:≥50KΩ |

| Defend Grade | IP65 |

| Safe Overload | 120% |

| Ultimate Overload | 150% |