- Overview

- Recommended Products

- Structural Design: Adopts an integrated parallel beam structure (beam body thickness 2-15mm, length 20-150mm), with uniform stress distribution concentrated in the middle section of the beam body, supporting multi-angle forces in the plane, featuring outstanding anti-eccentric load capacity (able to withstand plane eccentric loads of ±20%-±30% of the rated load), and no obvious stress blind spots.

- Precision Performance: Accuracy levels cover C1-C3, with mainstream models reaching C2. Nonlinearity error ≤±0.01%FS, repeatability error ≤±0.005%FS, zero drift ≤±0.002%FS/℃, and accuracy performance is superior to similar sensors in small-range scenarios from 0.1kg to 500kg.

- Materials and Protection: The elastic body commonly uses aluminum alloy (for lightweight scenarios), alloy steel (for conventional industrial scenarios), or 304/316L stainless steel (for corrosive scenarios), with the surface treated by anodizing, nickel plating, or passivation; the protection level is typically IP65/IP67, and food-grade models can reach IP68, suitable for various complex environments.

- Installation Compatibility: Standardized mounting holes (threaded holes or smooth holes) are provided at the bottom, supporting bolt fixing or adhesive installation. Some micro models can be installed in an embedded manner, suitable for the narrow installation space of desktop weighing instruments and automated equipment, and a single unit can meet the plane weighing requirements.

- Light Load Force Measurement: Focuses on static/quasi-dynamic light load weighing (response time ≤ 4ms), with a measurement range covering 0.1kg - 500kg. Regular applications are concentrated in the 1kg - 200kg range, and the micro model can achieve ultra-small range measurement of 0.01kg.

- Multiple Types of Signal Output: Provides analog signals (4 - 20mA, 0 - 3V, 0 - 5V) and digital signals (RS485/Modbus RTU, I2C). The micro intelligent model integrates a signal conditioning module and can be directly connected to single-chip microcomputers and IoT modules.

- Safety Protection Function: Integrates wide temperature range temperature compensation (-10°C ~ 70°C), has overload protection (150% - 200% of the rated load, usually 150% for aluminum alloy models), and some models include an anti-shock buffer structure.

- Long-Term Stability: Fatigue life ≥ 10⁷ cycles of load, with an annual drift ≤ ±0.01%FS under rated load, suitable for long-term continuous operation scenarios such as supermarkets and laboratories.

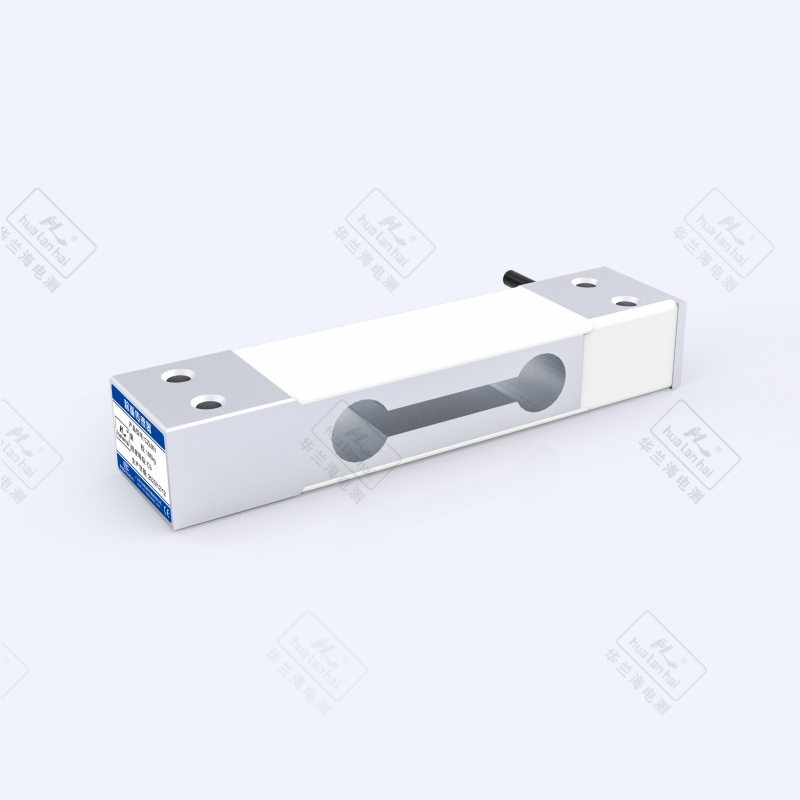

Product Introduction

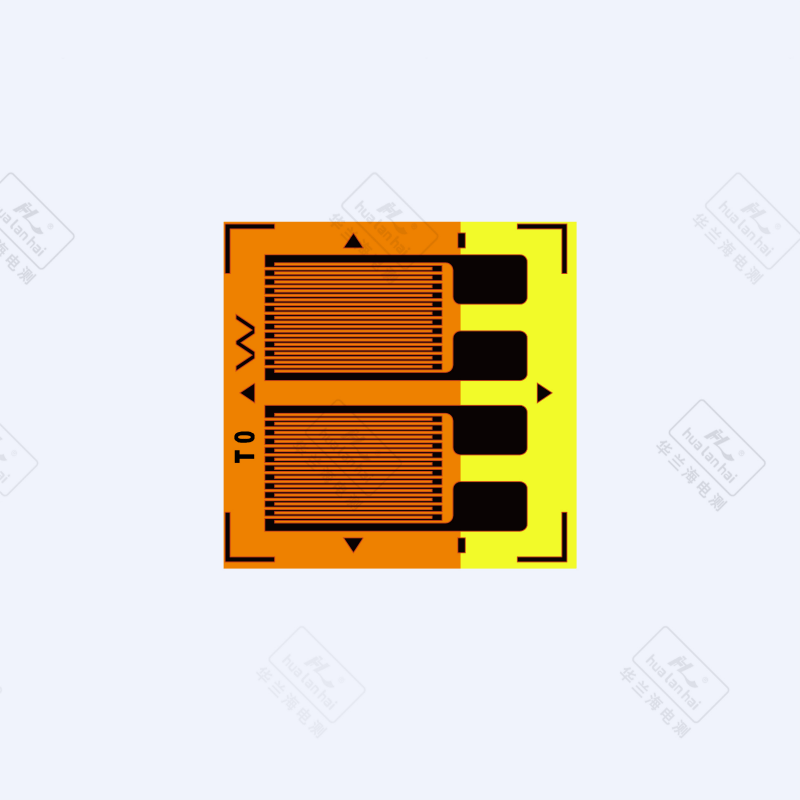

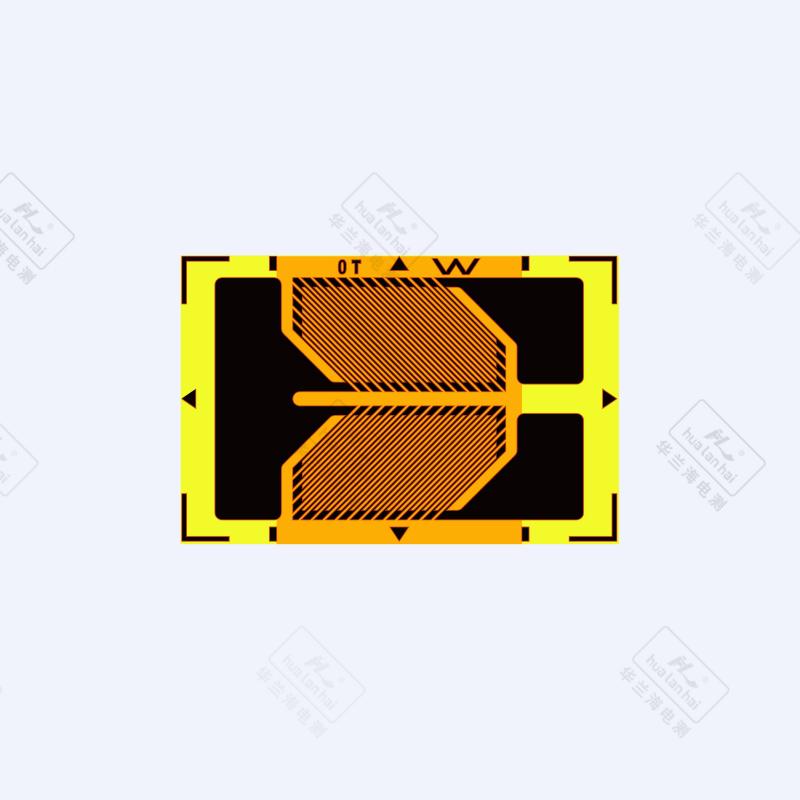

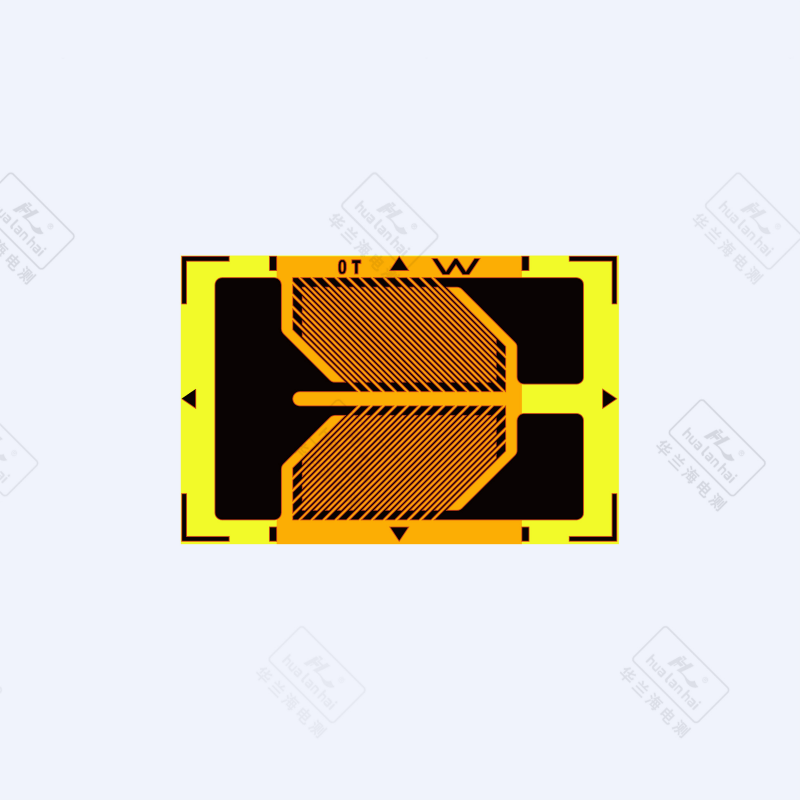

Parallel beam load cells are force-sensitive detection elements based on the strain resistance principle, with a double parallel beam or single parallel beam elastomer as the core structure. When subjected to force, the bending deformation of the beam drives the strain gauge to produce resistance changes, which are then converted into standardized electrical signals. They combine advantages such as high precision under light loads, planar anti-off-center load, and convenient installation, and are widely used in small-range weighing, planar force, and embedded measurement scenarios. The following details are presented from the core dimensions to meet the needs of product selection, technical evaluation, and solution writing:

1. Product Features and Functions

Core Features

Core Functions

2. Core Problems Solved

• Insufficient Accuracy in Light-load Scenarios: To address the issue of excessive error in traditional sensors for small-range scenarios below 10 kg, through optimized design of beam body stress, the measurement error is controlled within ±0.005%FS, meeting the high-precision requirements of food weighing, pharmaceutical metering, etc.

• Inaccurate Measurement of Planar Off-center Load: The uniform stress distribution characteristic of the parallel beam structure can effectively offset the influence of off-center load caused by the offset of the weighed object, solving the accuracy problem of non-fixed material placement positions in desktop weighing instruments and sorting equipment.

• Difficulties in Equipment Integration and Installation: The compact structure and flexible installation method address the embedded installation requirements of automated equipment and smart home appliances, eliminating the need to modify the main structure of the equipment and reducing integration costs.

• Poor Adaptability to Multiple Environments: Through material and protection level upgrades, problems such as sensor damage and signal drift in scenarios such as humidity (e.g., aquatic product weighing), corrosion (e.g., chemical reagent weighing), and dust (e.g., flour processing) are solved.

• Cost Pressure on Small Devices: A single sensor can meet the planar weighing requirements, eliminating the need for multiple sensors to be used in combination. Meanwhile, the aluminum alloy material reduces the product weight and cost, solving the cost control problem of small weighing instruments and consumer electronics.

3. User Experience

• Ultra-simplified Installation: Standardized mounting holes and positioning reference surfaces eliminate the need for professional calibration tools. Installation can be completed with an ordinary screwdriver, with low flatness requirements (≤0.1mm/m), and a single person can complete debugging within 10 minutes.

• Low Operation Threshold: Supports one-key zeroing and single-point calibration for weighing instrument meters (only requires a standard weight of 100% of the rated load). Digital models can be quickly calibrated via computer software, enabling non-professionals to operate easily.

• Extremely Low Maintenance Cost: The fully sealed structure reduces dust and moisture intrusion, with an annual average failure rate ≤0.2%. Aluminum alloy models are lightweight (minimum only 5g), easy to replace, and do not require disassembling large structures during maintenance.

• Precise Data Feedback: Static measurement data fluctuation ≤±0.003%FS, with no lag in quasi-dynamic scenarios. Digital models come with built-in zero drift compensation function, eliminating the need for frequent calibration and ensuring strong data stability.

• Good Integration Compatibility: Micro models are small in size (minimum dimensions 20mm×10mm×5mm), can be embedded inside smart devices without affecting the device's appearance design. Signal output is compatible with mainstream small controllers, supporting Plug and Play.

4. Typical Application Scenarios

1)Civil and Commercial Light Load Weighing Instruments

• Supermarket Pricing Scales/Electronic Platform Scales: Core sensing units for 3-30kg pricing scales, featuring lightweight design with aluminum alloy material, anti-eccentric load characteristics ensure consistent weighing accuracy at different placement positions, with an error ≤ ±1g.

• Express Delivery Electronic Scales: 1-50kg express delivery weighing equipment, made of stainless steel for anti-fouling and easy cleaning, IP67 protection rating suitable for the humid and dusty environment of express delivery outlets, supporting rapid and continuous weighing.

• Kitchen Scales/Baking Scales: 0.01-5kg high-precision kitchen scales, with micro parallel beam sensors achieving milligram-level accuracy, digital signal output compatible with high definition displays, meeting the need for precise ingredient proportioning.

2)Industrial Automation Equipment

• Automated Sorting Equipment: Weight sorters in the food and hardware industries, installed under the sorting conveyor belt, detect product weight in real time and link with the sorting mechanism, with sorting accuracy up to ±0.1g.

• Assembly Line Material Detection: Material shortage detection on electronic component assembly lines, determines whether materials are missing through weighing (e.g., mobile phone battery assembly), response time ≤ 4ms, suitable for high-speed assembly lines.

• Quantitative Control of Packaging Machines: Quantitative weighing for small particle/powder packaging machines, C2 grade accuracy models ensure that the weight error per bag ≤ ±0.2%, meeting metrological standards.

3)Food and Pharmaceutical Industries

• Pharmaceutical Ingredient Weighing: Weighing of small-dose raw materials (0.1-10kg) in the pharmaceutical industry, 316L stainless steel material + GMP certification, surface polished without dead corners, easy for disinfection and sterilization, accuracy ≤ ±0.01%FS.

• Aquatic/Meat Weighing: Cutting and weighing equipment in slaughterhouses and aquatic markets, waterproof and anti-corrosion design (IP68), can be directly washed, suitable for humid and water-rich working environments.

4)Scientific Research and Experimental Equipment

• Biological Experiment Weighing: Weighing of reagents and samples in laboratories, ultra-small range models (0.01-1kg) can meet the high-precision requirements of microbial culture and chemical reagent proportioning.

• Force Measurement of Medical Equipment: Force/weight measurement for rehabilitation equipment (e.g., handgrip dynamometers) and medical scales (baby scales), lightweight aluminum alloy design improves equipment portability, accuracy up to ±0.005%FS.

5)Smart Consumer Electronics and Internet of Things (IoT) Devices

• Smart Home Appliances: Detection of laundry weight in washing machines and weighing of coffee bean bins in coffee makers, micro embedded sensors enable intelligent control of devices, enhancing user experience.

•Internet of Things terminal: Weight monitoring for smart shelves and smart trash cans, low-power digital models support NB-IoT wireless transmission, suitable for IoT remote management scenarios.

5. Usage Instructions (Practical Guide)

1)Installation Process

• Preparation: Clean the installation surface (remove oil stains and burrs), check the appearance of the sensor (no deformation of the beam body and no damage to the cable), and select the appropriate mounting bolts according to the measuring range (avoid using high-strength bolts for aluminum alloy models).

• Positioning and Fixing: Horizontally install the sensor on the load-bearing surface, ensuring that the load acts vertically above the beam body (avoid lateral impact); use a torque wrench to tighten the bolts (5-10 N·m for aluminum alloy models, 10-20 N·m for alloy steel), preventing over-tightening from damaging the beam body.

• Wiring Specification: For analog signals, follow "red - power +, black - power -, green - signal +, white - signal -"; for digital signals, connect according to the pin definition; when wiring the micro model, avoid pulling the cable, and it is recommended to reserve 5 cm of redundant length.

• Protection Treatment: In a humid environment, seal the cable connector with waterproof tape; in the food industry, clean the sensor surface promptly after use to avoid corrosion from residual materials.

2)Calibration and Debugging

• Zero Calibration: Turn on the power and preheat for 10 minutes, execute the "zero calibration" command, ensure that the zero output is within ±0.001%FS, and if the deviation is too large, check whether the installation surface is flat.

• Load Calibration: Place a standard weight equivalent to 100% of the rated load (use standard weights in small measuring range scenarios), record the output signal value, correct the error through the meter or software, and ensure that the error ≤ the allowable value of the corresponding accuracy class (C2 class ≤ ±0.01%FS).

• Eccentric Load Test: Place the same weight at different positions on the load-bearing surface of the sensor, observe the consistency of the readings, and the deviation should be ≤ ±0.02%FS; otherwise, adjust the installation levelness.

3)Routine Maintenance

• Regular Inspection: Clean the sensor surface weekly, check whether the wiring is loose monthly; calibrate commercial weighing instruments quarterly, and laboratory equipment monthly.

• Fault Handling: When data drifts, first check the power supply voltage (stable at 5-24V DC, usually 5V for micro models); when the reading is abnormal, check whether there is an overload (aluminum alloy models are prone to permanent deformation under overload), and replace the sensor if necessary.

6. Selection Method (Precisely Match Requirements)

1)Determination of Core Parameters

• Range Selection: Select the model according to 1.2 - 1.4 times the actual maximum weight (e.g., for a maximum weighing capacity of 10 kg, a 12 - 14 kg sensor can be selected), and avoid selecting an excessively large range in light load scenarios to prevent insufficient accuracy.

• Accuracy Class: Select Class C1 (error ≤ ±0.005%FS) for laboratory/medical applications, Class C2 (error ≤ ±0.01%FS) for industrial metrology, and Class C3 (error ≤ ±0.02%FS) for civil weighing instruments.

• Signal Type: Select analog signals (0 - 5V) for civil weighing instruments, digital signals (I2C/RS485) for smart devices, and models with wireless modules for IoT scenarios.

2)Selection Based on Environmental Adaptability

• Temperature: Select ordinary models for normal scenarios (-10°C ~ 60°C), low-temperature-resistant models for low-temperature refrigeration scenarios (-20°C ~ 0°C), and high-temperature compensation models for high-temperature scenarios (60°C ~ 80°C).

• Medium: Select aluminum alloy for dry environments, 304 stainless steel for wet/food industries, and 316L stainless steel for chemical corrosion environments.

• Protection Class: ≥IP65 for indoor dry environments, ≥IP67 for wet/washed environments, and ≥IP68 for underwater or highly corrosive environments.

3)Installation and System Compatibility

• Installation Method: Select bolt fixing for desktop weighing instruments, embedded installation for smart devices; in space-limited scenarios, prioritize micro models with a length ≤30 mm.

• Compatibility: Confirm that the sensor's power supply voltage and signal type match the controller. For micro models, check the pin definitions to avoid wiring errors that could burn out the module.

4)Confirmation of Additional Requirements

• Certification Requirements: The food and pharmaceutical industries require FDA/GMP certification, metrology scenarios require CMC certification, and export products require OIML certification.

• Special Functions: Select models with a response time ≤3 ms for high-speed sorting, IoT models with a standby current ≤10 μA for low-power scenarios, and integrated models without threads and dead corners for hygienic scenarios.

Summary

The parallel beam load cell features "light load high precision, planar anti-off-center load, and convenient integration" as its core advantages, primarily addressing issues such as accurate weighing of small ranges, material off-center load, and embedded installation of equipment. User Experience focuses on simple operation, worry-free maintenance, and controllable costs. When selecting a load cell, it is necessary to first clarify the four core requirements of range, accuracy, installation space, and environment, and then make a decision in combination with system compatibility and additional functions; during use, overload and lateral impact should be avoided, and the regular calibration specifications should be strictly followed to ensure long-term stable operation. It is suitable for applications in light load weighing instruments, automation equipment, food and medicine, and other fields, and is the optimal sensing solution for small range and planar weighing scenarios.

Detail Display

Parameters

| Parameter Name | Parameter Value |

| Sensor range | 3kg ~ 120kg |

| Accuracy class | C2 |

| Comprehensive error | ±0.03% FS |

| Output sensitivity | 2.0±0.2 mV/V |

| creep | ±0.023% FS/30min |

| Zero output | ±1.5% FS |

| Input impedance | 405±10Ω |

| Output impedance | 350±5Ω |

| insulation resistance | ≥5000 MΩ(100VDC) |

| Influence of zero temperature | ±0.029% FS/10℃ |

| Sensitivity temperature effect | ±0.025% FS/10℃ |

| Temperature compensation range | -10℃ ~ +40 ℃ |

| Operating temperature range | -20℃ ~ +60 ℃ |

| Excitation voltage | 5VDC ~ 12VDC |

| Safe overload range | 120% |

| Limit overload range | 150% |

| Recommended table size | 300*350mm |

| Material Science | Aluminum Alloy |

| Protection level | IP65 |

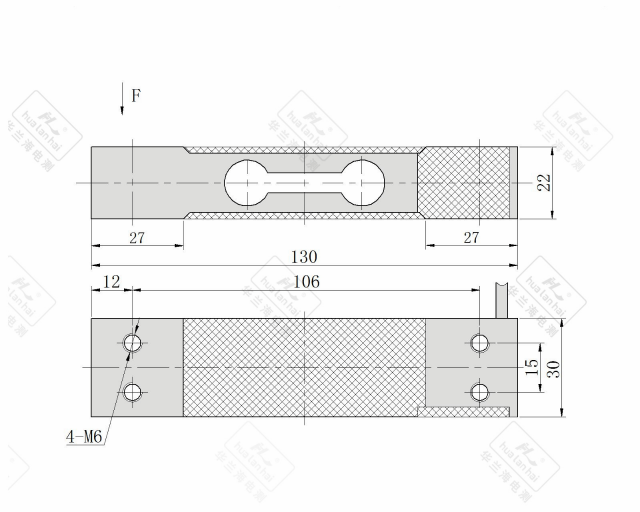

| External dimension of sensor | 1303022 |

| Mounting hole size | 2-M6 |

| Location of mounting hole | Y15 |