- Overview

- Recommended Products

- Ultra-compact and lightweight: Standard sizes range from 5mm×5mm×2mm to 30mm×20mm×10mm, with some custom models shrinking to millimeter-level dimensions and weighing just 0.1g to 5g. These components can be seamlessly integrated into tight spaces like smartwatches and miniature pump housings without compromising the devices structural integrity.

- Compact design: Most models feature integrated packaging that combines sensitive components and signal conditioning circuits within a micro-sized housing. Some variants support slim mounting solutions like surface-mount technology (SMT) or lead-type connections, compatible with direct PCB soldering or snap-fit mounting.

- Wide-range precision measurement: The system covers a range of 0.1g to 50kg, with core measurement accuracy of ±0.01%FS to ±0.1%FS and resolution up to 0.001g. It meets both laboratory microgram-level sample weighing requirements and consumer electronics gram-level weight monitoring needs.

- Rapid dynamic response: With a response time of ≤10ms, it captures instantaneous weight changes in real time, such as high-speed light-load weighing in automated sorting lines and drip rate/weight monitoring in medical infusion systems, thus preventing measurement deviations caused by signal delays.

- Stable anti-interference capability: The built-in temperature compensation module (operating in-10℃ to 60℃) counteracts environmental temperature fluctuations. Featuring differential signal output or electromagnetic shielding, it effectively resists internal circuit interference, ensuring data stability.

- Multi-output compatibility: Supports analog signals (0-5V,4-20mA) and digital signals (I2C, SPI, UART), enabling direct interfacing with microcontrollers, single-chip microcontrollers, and compact PLCs without requiring additional signal amplification modules.

- Material and medium compatibility: The sensitive components are primarily made of 316L stainless steel, titanium alloy, or engineering plastics, with corrosion-resistant casings. These components are compatible with various weighing media including medical fluids, food ingredients, and electronic components, effectively preventing contamination or corrosion damage.

- Low-power performance: Static power consumption ≤10mA, dropping to 10μA in sleep mode, ideal for battery-powered portable devices (e.g., handheld scales, smart wearables) to extend battery life.

- Challenges in micro-device integration: Addressing the inability of traditional sensors to be embedded in compact devices, such as the weight monitoring function in smart wristbands or the liquid dosage control in micro-medical pumps, by achieving both weighing functionality and miniaturization through compact design.

- The problem of light load and high precision measurement: to solve the problem of insufficient accuracy of traditional sensors in gram and milligram scale weighing, such as laboratory micro sample weighing, electronic component pin weight detection, to provide reliable data for precision production and scientific research.

- Power efficiency challenges for portable devices: To address the issue of short battery life caused by high power consumption in traditional sensors, such as handheld parcel scales and outdoor sample collection weighing equipment, these devices feature low-power characteristics to extend their single-use duration.

- Complex installation space constraints: Addresses weighing requirements in confined or structurally unique environments, such as internal component weighing for automated equipment and fluid weight monitoring in pipelines, by utilizing surface-mount or embedded installation solutions to overcome spatial limitations.

- Multi-scenario signal compatibility: It resolves the mismatch between traditional sensor signals and microcontroller units. The digital signal output model can directly interface with microcontrollers (MCUs), simplifying circuit design for compact devices and reducing R&D costs.

- High integration convenience: Standardized pin layout and package dimensions enable direct PCB soldering or snap-fit fixation without complex mechanical structures, reducing integration time to under 30 minutes and significantly boosting equipment production efficiency.

- The debugging process is straightforward: digital signal models allow one-click calibration of zero point and range via commands, while analog signal models feature excellent linearity. With just basic circuit debugging, they can be deployed immediately, significantly lowering the technical barrier for R&D teams.

- Highly reliable performance: The temperature compensation and anti-interference design ensure data drift remains ≤±0.05%FS/year, eliminating the need for frequent calibration in portable or embedded applications and significantly reducing maintenance requirements.

- Flexible model selection: A wide range of models with different measurement ranges, signal types, and installation methods are available. You can directly select the model based on equipment size, power supply voltage, and precision requirements. Some manufacturers also support small-batch customization to meet personalized needs.

- The cost control is reasonable: the unit cost can be controlled in dozens to hundreds of yuan when purchasing in batches, which is more than 50% lower than the customized micro sensing scheme. Meanwhile, the low power consumption characteristics reduce the overall energy consumption cost of the equipment.

- Infusion monitoring devices: Integrated into infusion pumps, they monitor real-time changes in solution weight, calculate infusion rates, and trigger alarms when the solution is nearly depleted to prevent empty bottles, as seen in precision infusion control in intensive care units.

- Rehabilitation and nursing equipment: including smart rehabilitation scales and prosthetic weight sensors, which monitor weight fluctuations during elderly rehabilitation training or provide force feedback for prosthetics, thereby enhancing rehabilitation safety.

- Laboratory equipment: Micro-pipettes and biochemical analyzers are used to measure reagent or sample weights, ensuring precise sample addition, such as the weighing of micro-samples for COVID-19 testing kits.

- Smart wearables: Integrated into fitness trackers and smartwatches, these devices enable indirect measurement of body weight and body fat, as well as real-time force monitoring during physical activities, such as analyzing foot strike weight during running.

- Smart home devices: Used for ingredient weighing in smart kitchen scales and coffee machines, such as precise measurement of coffee powder to control brewing concentration; or overflow monitoring in smart trash bins (determining waste capacity through weight).

- Portable weighing devices, such as mini parcel scales and luggage scales, feature compact designs and low power consumption, enabling users to carry them conveniently while measuring item weights in real time.

- Electronic component manufacturing: In SMT (Surface Mount Technology) assembly lines, monitor the weight of components like chips and resistors to screen out defective items; or in semiconductor packaging, measure the weight of encapsulant to ensure packaging quality.

- Micro-automation equipment: An end effector for micro-assembly robots that senses and weighs components to determine successful grasping, such as in smartphone camera module assembly weighing detection.

- Fluid control devices: embedded in micro metering pumps and fuel injectors, they monitor fluid delivery by weight, such as precise fuel weighing in fuel injection systems, to ensure combustion efficiency.

- Materials science research: Measuring the weight of tiny material samples (e.g. nanomaterials, thin films) or weight changes during tensile or compressive processes to provide data for performance analysis.

- Environmental monitoring equipment: In micro water quality monitors and air sampling devices, the weight of collected samples is measured to calculate pollutant concentrations, such as weight analysis of atmospheric particulate matter after sampling.

- Micro sorting system: At the end of the automated sorting line for express delivery, it weighs small parcels to classify them by weight; or at the self-service checkout counters in unmanned supermarkets, it identifies products through weighing (with the aid of a weight database).

- Retail weighing equipment, such as jewelry scales and precious metal scales, is designed for precise measurement of valuable items like gold and diamonds. Compact in size, these devices can be easily placed on counters without taking up much space.

Product Introduction

Micro weighing sensor:

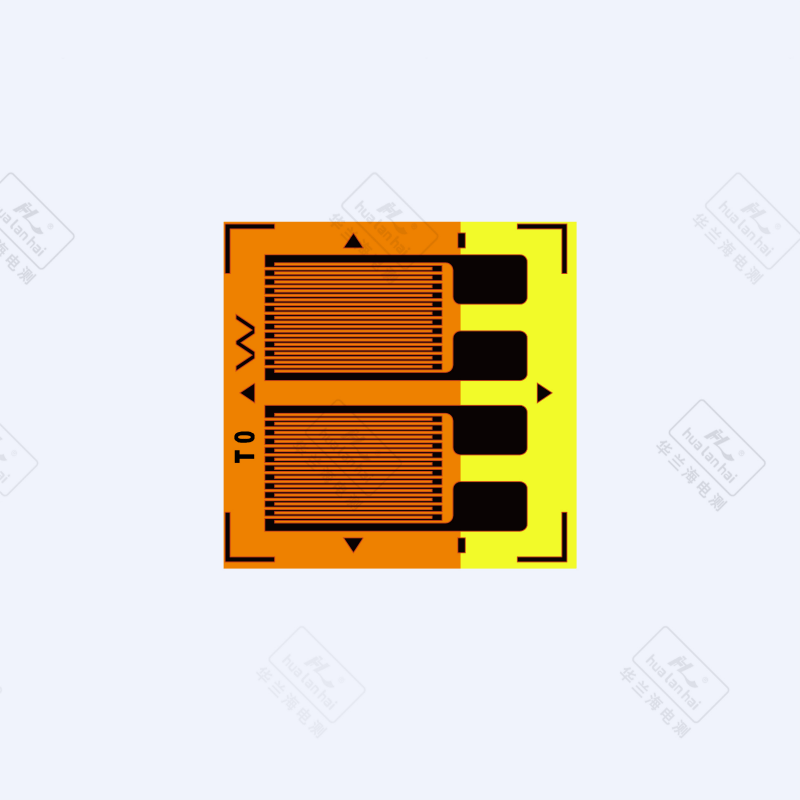

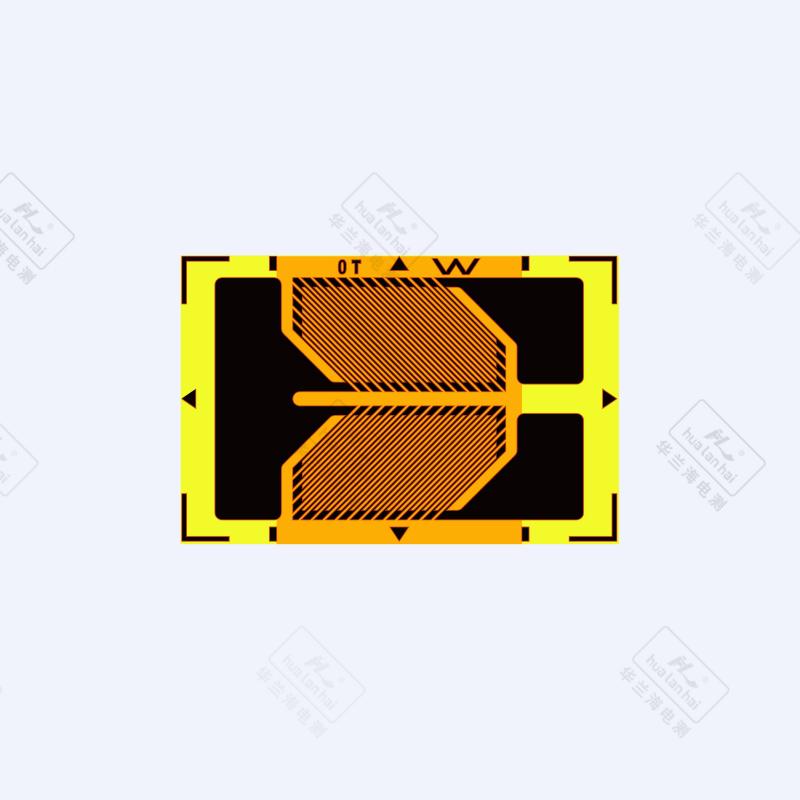

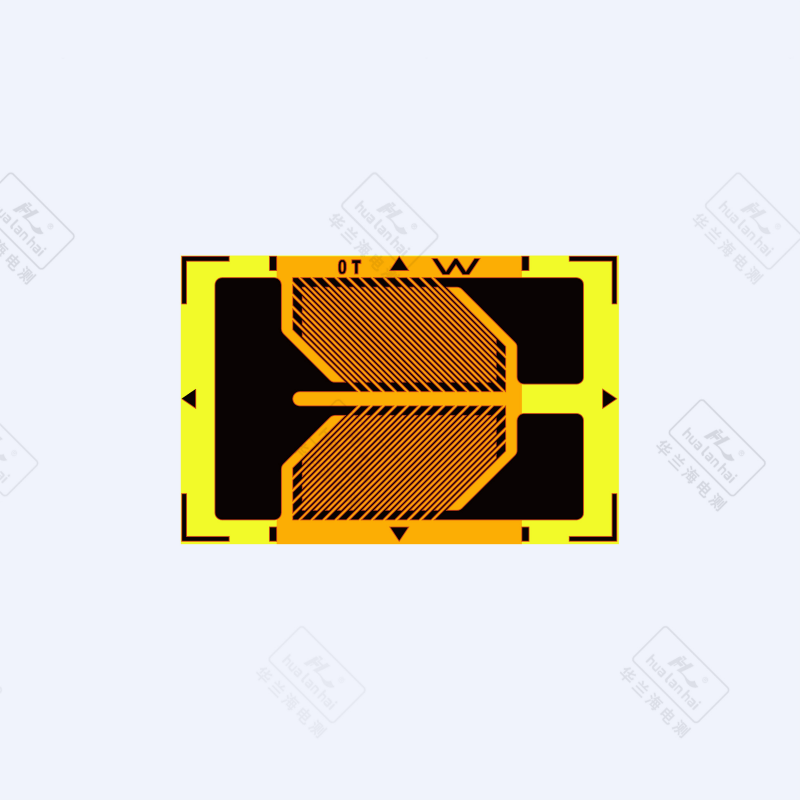

Micro-scale weighing sensors are compact weight measurement devices developed through strain effect technology. Their core mechanism involves converting weight signals into measurable electrical signals via micro-scale sensitive structures (e.g., strain gauge-based elastomers). Typically measuring just a few to dozens of cubic centimeters, these sensors operate across a range from grams to kilograms, combining the dual advantages of compact size and high precision. As essential components for lightweight and confined-space weighing applications, they are widely used in medical equipment, consumer electronics, smart devices, and scientific research testing, serving as the fundamental technology for weight sensing in miniature systems.

1. Core Features And Functions

1) The Core Feature of Miniaturization

2 )Weighting Performance Advantages

3)Integration And Adaptation Functions

2. Core Industry Pain Points to Be Resolved

In light-load and miniaturized weighing scenarios, traditional weighing sensors (e.g., platform scale sensors and industrial weighing modules) face challenges like excessive size, high power consumption, insufficient accuracy, and integration difficulties. Micro weighing sensors specifically address these core pain points:

3. Highlights of User Experience

4. Typical Use Cases

1) Health Care

2) Consumer Electronics And Smart Wearables

3) Industrial Automation And Micro-manufacturing

4) Research And Testing Fields

5) Logistics And Retail Sectors

Summary

Micro weighing sensors, with their core strengths of "compact size, high precision, and low power consumption," have overcome the spatial and measurement limitations of traditional weighing devices. They precisely meet the light-load weighing demands in fields such as medical, consumer electronics, and micro-manufacturing. Their convenient integration, stable performance, and cost-effective design not only drive functional upgrades in micro-devices but also provide reliable support for industries to achieve "precision, miniaturization, and intelligence" in weighing. As a result, they have become an indispensable branch of modern sensing technology.

Detail Display

Parameters

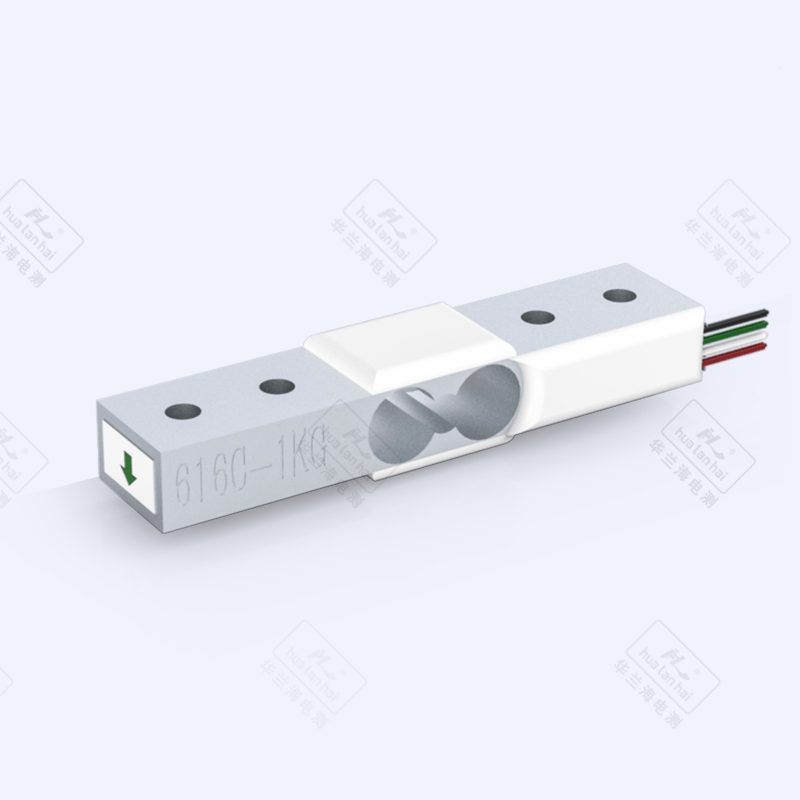

| Parameter Name | Parameter Value |

| Rated load | 10kg ~ 40kg |

| Zero output | ±0.2 mV/V |

| Output sensitivity | 1.1±0.1 mV/V |

| linear | 0.1% FS |

| lagging | 0.1% FS |

| Repeatability | 0.05% FS |

| Creep | 0.05% FS/3min |

| Output (input) impedance | 1000±50Ω |

| Service temperature | -10℃ ~ +40 ℃ |

| Zero temperature effect | ±0.1% FS/10℃ |

| Sensitivity temperature effect | ±0.1% FS/10℃ |

| Insulation resistance | ≥2000MΩ |

| Working temperature | -10℃ ~ +40 ℃ |

| Excitation voltage | 3VDC ~ 10VDC |

| Ultimate Overload | 120% FS |

| Comprehensive accuracy | 0.3% FS |

| Material Science | Manganese Steel |

| Protection level | IP65 |

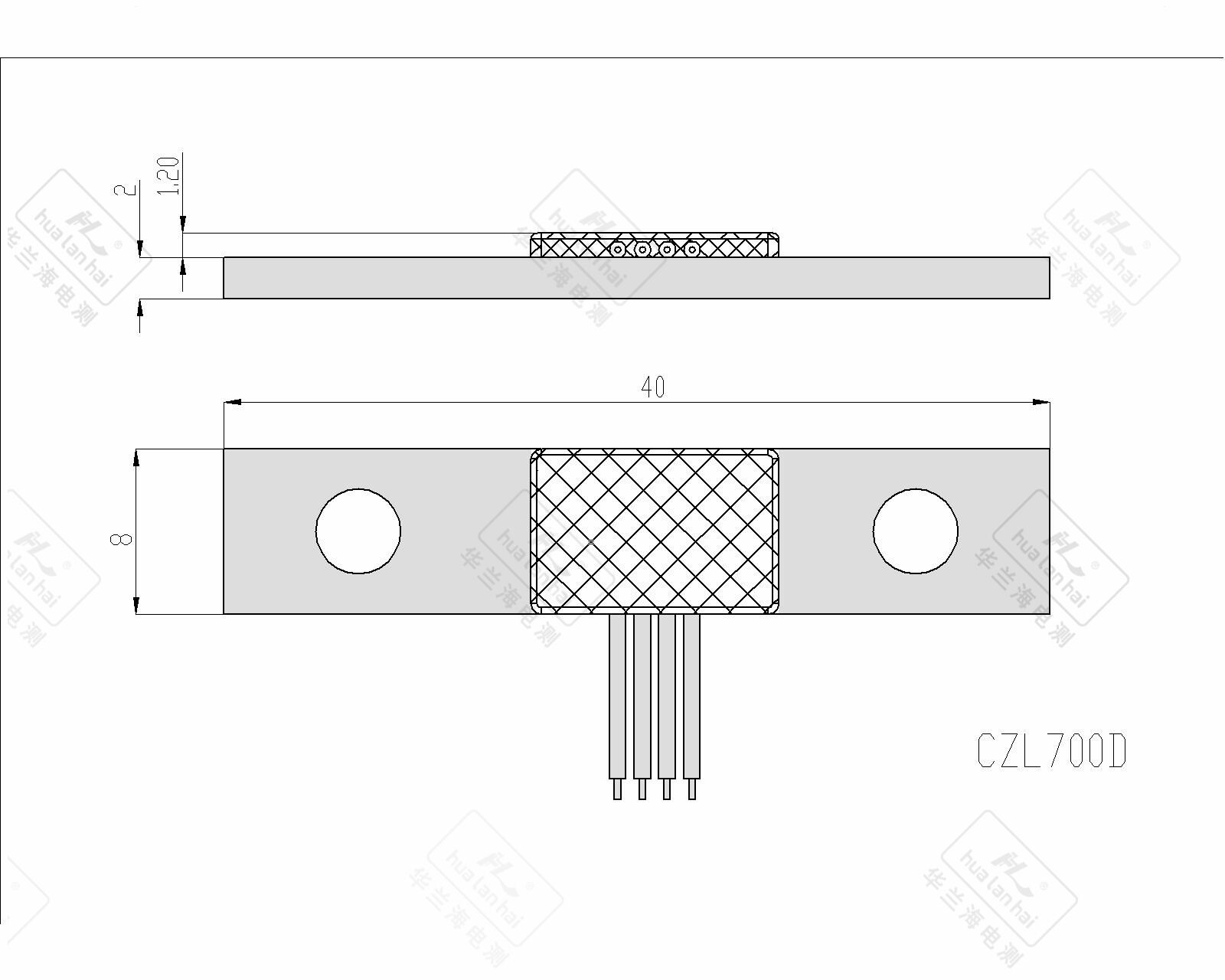

| Overall dimension of sensor | 408h |